ABOVE: The VP9 is inspired by the Welrod design but modernized for Veterinary use.

The legendary silenced Welrod pistol that was developed during the Second World War for special operations has found a worthy successor thanks to the Swiss special weapons producer B&T (formerly Brügger & Thomet). It is called the VP9 and remains a modern, compact and extremely quiet weapon. The primary mission of this product however, is not as “Top Secret” as with the Welrod.

The Welrod was developed during the Second World War for use by the British SOE and U.S. OSS and its first deployment was in the fall of 1943. Records indicate that 2,800 pieces of this special weapon were produced in total. Since then it has been regarded as the benchmark of practically all specifically designed suppressed clandestine weapons. Small Arms Review covered the Welrod in much greater depth some years ago and the reader can refer to these well written and in-depth articles by Anders Thygesen in the January and February 2006 issues of SAR (available online at www.smallarmsreview.com).

B&T presented at this year’s IWA show in Nuremburg, Germany the VP9, a pistol that is very similar to the design principles of the Welrod of many years ago combining the same basic principles with modern materials and technology.

The Company

In the world of the police and military small arms and accessories, B&T is a well-known and a highly respected manufacturer. For the last twenty three years the company has produced suppressors and weapons for Law Enforcement, Special Forces and internal security. This small but dynamic and highly innovative company is located in Thun, Switzerland. B&T suppressors are used by virtually all major European arms manufacturers and if one of the major OEMs in Europe deliver a weapon with a suppressor it is more likely than not a B&T suppressor. B&T is regarded as the world’s leading suppressor manufacturers with B&T products being used in more countries worldwide than any other.

Though the company started out in 1991 building suppressors, they now also produce weapons for law enforcement and the military. Some of the weapons produced by B&T include the MP9, APC9, SPR300, APR308 sniper rifle and the new APC556 and APC300 carbines chambered and qualified for the .300 Whisper cartridge. There are several more products in the works but that is perhaps for a later time.

Application of the Veterinary Pistol 9mm

The VP9 may have it roots in the Welrod but it has in reality a completely different purpose than its predecessor. The abbreviation VP9 stands for Veterinary Pistol 9mm. The intended purpose of this weapon is the quick and humane dispatch of sick and wounded animals.

The operator’s manual that B&T is preparing with the gun has diagrams of where to aim exactly on certain animals to ensure a swift and painless death. The brain cavity is placed in much different places on different animals, i.e., the point of aim on a horse is different than on a pig, which is different than on a cow. A veterinarian will know this but this weapon may also be used by a law enforcement officer or an animal control officer who may not be familiar with a particular animal’s physiology for a proper and humane euthanasia shot.

Veterinarians often use an injection to euthanize sick animals, but there are many cases where this cannot be done without risk. This is especially true with larger or more dangerous animals. Of course, a normal firearm, in such a case, can be used, but for a vet who is not experienced in dealing with weapons, a single shot and easy to use weapon presents a significant safety advantage. In addition, the integrated silencer is also a safety benefit. It not only prevents hearing damage of those present, but will also ensure that other animals in the area are not panicked. The reduced sound of the gunshot will also greatly aid in communication between the people present. Hearing also will not be encumbered by hearing protection.

Another salient point is the appearance of the weapon. The VP9 looks more like some kind of tool than a weapon. The handle (magazine) disappears completely in the hand and the otherwise characteristic trigger guard is missing. It doesn’t look scary in the mind of the good citizens in the area or other unrelated third parties. The sound of an unsuppressed gunshot could create unwanted attention or anxiety. The low report that is muffled and disguised will alleviate this. Additionally, the lowered velocity of the 9mm FMJ has a much lower risk of doing greater damage if exiting the head of the animal.

The Suppressor

Normally a weapon is constructed and the silencer is then adapted to the weapon itself. In this case with the VP9 it was vice versa. The B&T suppressor designers were able to draw on the wealth of their suppressor experience in the company and the optimal suppressor was designed and constructed first. Only afterward was the appropriate weapon developed to be put behind the suppressor.

The suppressor itself has a diameter of 35 mm and a length of 154 mm. At the rear end, it has a threaded socket for mounting on the barrel. The connector is located in the rear of the suppressor by a 35 mm long expansion chamber, which we can refer to as the second expansion chamber. In front of this there are three further chambers; each chamber being 17 mm long. The chambers are separated from each other by synthetic discs 6 mm thick. These discs are pre-cut in the center crosswise in order to allow a projectile to slip through the suppressor, while the remaining gases are trapped behind. This system works extremely well for sound reduction but what is really interesting is when one opens the action of the VP9 for a follow up second shot there is actually a slight jet sound as the trapped gases escape. This indicates how tight the system is contained and how well it functions in gas retention.

Although the synthetic discs maximize the sound reduction, these have a short service life as the reduction capacity will decrease after about ten shots. One can expect to fire a maximum twenty rounds with the operational field suppressor before changing the discs are required. It makes little sense to train with these types of baffles as one would be forced to change the baffles regularly. To encourage practice, B&T offers a training suppressor system. This baffle system is made of alloy and though is not as dramatic in sound reduction it is still well below the 140 dBA. (dB measures sound pressure levels that are unweighted. dBA levels are “A” weighted according to the weighting curves that approximate the way the human ear hears.) It is virtually maintenance free and can be shot for thousands of times. It is practically identical to the external dimensions of the operational baffles but consists of four different pieces and corresponds to the well-known and widely used Impuls IIA suppressor – the same suppressor that B&T sells to most of Europe’s pistol producers.

The Suppressor’s Performance

Many times statements made by some producers about the sound reduction of certain products often seem rather ambitious. Suppressor reduction claims always needs to be treated with extreme caution; not to mention the general public is “tainted” by cinema and television in terms of the sound a suppressed weapon will produce.

In reality, the method of measuring sound reduction is governed by a Mil-Std (Military Standard). The only serious and scientifically recognized method of conducting this type of testing is governed by Mil-Std-1474 D. When measured according to this test protocol, the actual report of the VP9 is well below 129 dBA when using standard FMJ ammunition. This corresponds to noise of an air rifle. As a matter of fact, the sound of the operator manipulating the action makes more noise than the report the weapon produces.

The Gun

The receiver of the weapon itself and various attachments actually forms different components of the system. The first part of the system is the receiver. It is in cylinder form and produced of standard ordinance grade steel that is 130 mm long and 32 mm in diameter. The barrel is threaded and screwed into the recess of the receiver. The barrel is quite short being 50 mm long and has fifteen holes evenly drilled around the diameter of the barrel. The only part that extends from the receiver is the threaded part of the barrel that is about 10mm in length. This barrel design will ensure that the gas pressure of a standard velocity 9mm projectile is reduced to below 300 meters per second. The reason for this configuration is quite simple: it will ensure that the operator will not be dependent on subsonic ammunition to achieve the maximum results regarding noise.

The locking system is somewhat like a bolt action rifle. It has two locking lugs not unlike a standard Mauser system. The locking lugs each have 30 mm² area. To unlock the system, take the bolt head at the end of the weapon between the thumb and index finger and turn the lock 90 degrees to the left. Then pull the bolt to the rear until the action is open. To load the weapon for the next shot, simply push the bolt closed and turn the bolt head 90 degrees to the right to lock the bolt in battery. A fresh cartridge will be fed from the magazine and chambered as the bolt closes. There is a red line on the top of the bolt and receiver that should be lined up. Repeat the process to eject the spent case and to reload a fresh round.

The magazine functions as the handle grip of the weapon. This feeding device has a molded handgrip applied directly onto the magazine. The extension that the magazine fits into extends 28 mm below the contour of the receiver. This extension could be called the trigger assembly as the trigger feeds into it as well. It also contains the magazine release and safety. The safety is activated by pushing the knob from left to right.

The Magazine

One of the design considerations of the weapon application was that it be as compact as possible. To fill this requirement, B&T has utilized the single-row magazine of the SIG P225; though this magazine has been modified to accept a capacity of only 5 rounds. This plus one in the chamber gives the operator 6 rounds in total. The magazine is further modified by having a polymer grip shroud that functions as a grip. Standard P225 magazines without the shroud cannot be used. The operator can see how many rounds are left in the magazine by observing the holes on the side. Height of the weapon with the magazine inserted is just shy of 114 mm. The height minus the magazine is only 63 mm. The weapon can be fired without the magazine inserted.

The Accessories

It can be expected that the weapon could be used during hours of darkness or at least at twilight. It is for this reason that the VP9 has a NATO Accessory Rail that can be mounted on the tube of the suppressor. This will enable the operator to mount either a light or a laser or combination of both. There is also a rather nice transportation box made of leather which is more like an attaché case. Inside, the foam is cut out for all the accessories. There is another bag that that can be worn over the shoulder or around the waist. There is a flap at the muzzle end so the weapon can be fired while still being in the case. When the weapon is disassembled it fits nicely into the case as well.

On The Range

During the preparation of this report B&T was in the process of conducting firing tests of the VP9 in one of their in-house shooting ranges. In this test there were a total of 500 shots fired from the test weapon to see what potential problem might develop in either accuracy or functioning. Every stoppage was analyzed and logged so that it could be discussed with engineering to see if there was the need for some modifications in the design. Such tests need to be completed during the development phase of the project before it gets turned over to production. This is an important part of the development because despite the entire CAD design process and simulations these experiments provide valuable insights to the actual performance of the product. With a weapon like the VP9 it is not required to do a 20,000 round torture test to see what failures may or may not develop as with a select fire weapon like the APC or MP9.

The author was present during this test and fired the weapon quite a bit and can state that after about 200 rounds one could feel the fact that the grip is not an ergonomic miracle. The fact that the gun is a bolt action pistol, there is no opposing recoil force to mitigate the recoil impulse. However, in training, only about 20-30 rounds would be necessary as distances would be so short and in service, use would only be one or two rounds at a time.

Precision

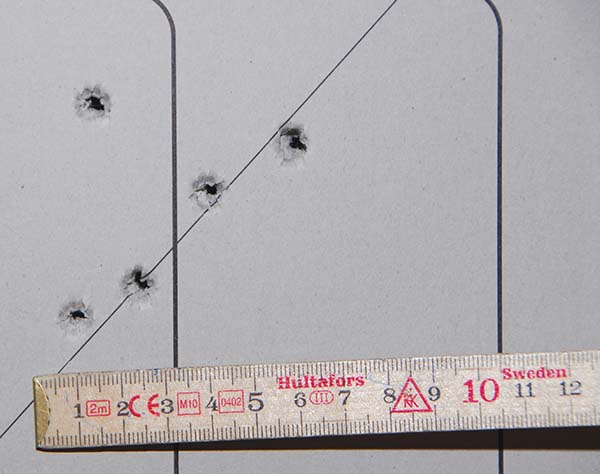

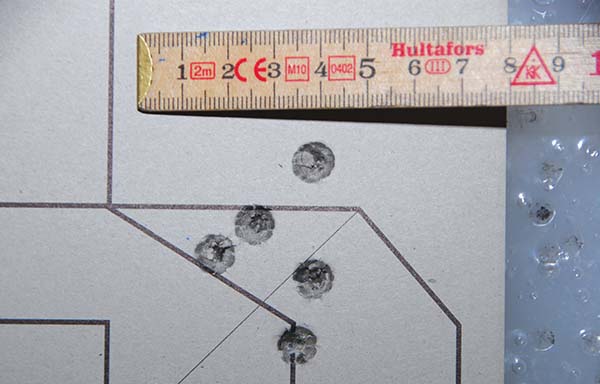

The barrel length of the VP9 is only 50 mm, of which 16 mm of that is the chamber, so actually the barreled part is only 34 mm. In addition, the bullet must still pass through the 4 polymer discs, so with respect to the precision one cannot expect too much. It isn’t a sporting gun… On the other hand, one must understand that such a weapon will rarely be fired at distances more than 5 meters. We conducted a test by shooting at a target at a distance of 10 meters. The primary concern was to determine the accuracy; a laser aiming module was mounted. There was no Ransom Rest possible. We shot a 5 shot group at 10 meters with both the training suppressor and the field suppressor. The groups were: 37mm with the training suppressor and 48mm with the field suppressor. The difference with the synthetic discs is evident. For a closer distance of say 5 meters the accuracy would be half for a head shot of an immobile yet wounded animal.

Conclusions

The B&T VP9 is a very interesting product that meets a wide variety of applications. In this sense it seems to be more of a tool than a weapon. In conversations with some of the B&T employees they would sometime refer to it as the “Device.” The two weapons used in these tests are pre-production samples, one of which has already been shot more than 500 times. So it is not possible to say anything regarding the surface treatment. In the past however everything that B&T has produced has performed well so there is no reason to expect the production series will not perform as well. Another point that takes a bit of getting used to be that to eject an expended shell and before chambering a second round one must turn the device 90 degrees either to left or right so the round can be ejected. With a little training it goes quite fast but it does take some getting used to.

This is surely is an interesting item and let’s just hope that where such devices are not considered legal, the legislation soon changes. It makes sense in terms of animal welfare and to protect the hearing of users and bystanders.