Since 2016, U.S. Ordnance has been the sole supplier of the U.S. Model MK19 Mod 3 and Mod 4 machine guns to U.S. military and other government agency end-users. In 2022, they were issued the NSN as sole supplier with an IDIQ contract of up to $50m. As we go to press, they are in the first article testing phase of the contract, and we were allowed to participate in the testing. We previously reported on Phase I, and now we report on Phase II here. It’s an extensive inspection and live firing test.

Since U.S. Ordnance received the NSN and contract, they must perform “first article” inspection and testing. There are more than 186 parts inspections that must be accomplished. Each one must meet the military standards for production. There is also a testing protocol called for in MIL-G-70790 (AR), the Military Specification for Gun, Machine, 40mm MK19 Mod 3, which must be strictly adhered to and passed with government inspectors viewing. In the previous article, we reviewed the relevant first parts of the testing we observed. Now it’s time to go live, but there are more checks to perform before we can start.

MK19 Mod 3 Specifications

| Caliber | 40x53mm |

| Weight | 77.6 lb. (35.2kg) empty |

| Length | 43.1 in. (1090mm) |

| Width | 9.46 in. (240.4mm) |

| Barrel Length | 16.25 in. (413mm) (Removable) |

| Muzzle Velocity | 750-790 fps (230-240 m/s) |

| Effective Firing Range | 1,500m (1,600 yards) |

| Maximum Firing Range | 2,212m (2,419 yards) |

| Feed system | 32 or 48 grenade belts in metal can, M16A2 link |

In section 3.3 of the Mil-Spec, gun sights and bore calibration are checked. The wedge optic mount on the right side in the MWO has to be perfect for calibration, which we did check. Then, in 3.4 and 3.5, it’s an ammunition compatibility check to ensure all the various 40x53mm rounds will chamber and fire. Done. Then, as stated in 3.5.1, “Proof Testing: The machine gun shall withstand the firing of one M385A1 40mm cartridge without any evidence of part failure, deformation, or loosening.” Done.

The M385A1 round has a one-piece solid aluminum projectile with a rotating band in an M169 cartridge case. The propellant is M2 (4.2g, 0.15 oz.). The primer is an FED 215 percussion-type. The ogive of the M385 series matches the shape of the M430/A1 HEDP projectile, which has 45g (1.61 oz.) of Comp A5 explosive, a shaped charge with copper liner, and a pre-fragmented body. It’s just the ogive that matches. The M385 series frequently is indented at center, which is weight lightening to match the weight of the M430 round. The M385A1 uses M16A2 links only (The M385 can use either M16A1 or A2).

There are protocols, as mentioned. Firing must be done in a proper, specified cadence to allow proper cooling periods, simulating the long life of a MK19 Mod 3 in service. Cleaning intervals must be followed, as well as inspections, including some testing that might appear redundant, but is necessary to achieve the full results of the test.

Benchmarks in the MK19 Mod 3 MIL-Spec First Article Acceptance Test

(SADJ covered many of these items in the first article in this series, it is online at www.sadefensejournal.com, if you would like to refer to it).

Spoiler Alert: U.S. Ordnance’s MK19 Mod 3 program has passed all of the MIL-Spec testing and is in the third phase. They are the only source of U.S.-made MK19 Mod 3 machine guns accepted by the U.S. military.

- Pre-Firing Inspection There are 19 points to cover in this visual inspection.

- Ammunition Compatibility Check This is done with a variety of issue rounds supplied by the customer. There are 12 steps in this process, covered in our first article.

- Gun Sight and Bore Calibration Check There are 12 steps in this process, covered in this article.

- Proof Inspection This is a 3-part inspection involving firing on round of M385A1 ammunition.

- Firing Mode This is a test in 8 parts of the firing mechanism including the solenoid remote firing.

- Belt Pull A four-part test, done with free hanging 28-round belts, in two to four round bursts. We performed this test in the first article, but again throughout the second testing.

- Cycling Rate of Fire Measured with 10-round belts. Interestingly, the string of rounds is not averaged for rate of fire but measured individually to meet the required rate.

- Trunion Load Performed in the test report in this article.

- Accuracy At 1000m, a 14m target is set. Firing is done in 2-3 round bursts and all rounds must hit the target. Performed both test days we were there for.

- Post-Firing Cleaning At all times that are called for, a full inspection is done for proper cleaning and reassembly. Parts are inspected according to 9 focus points.

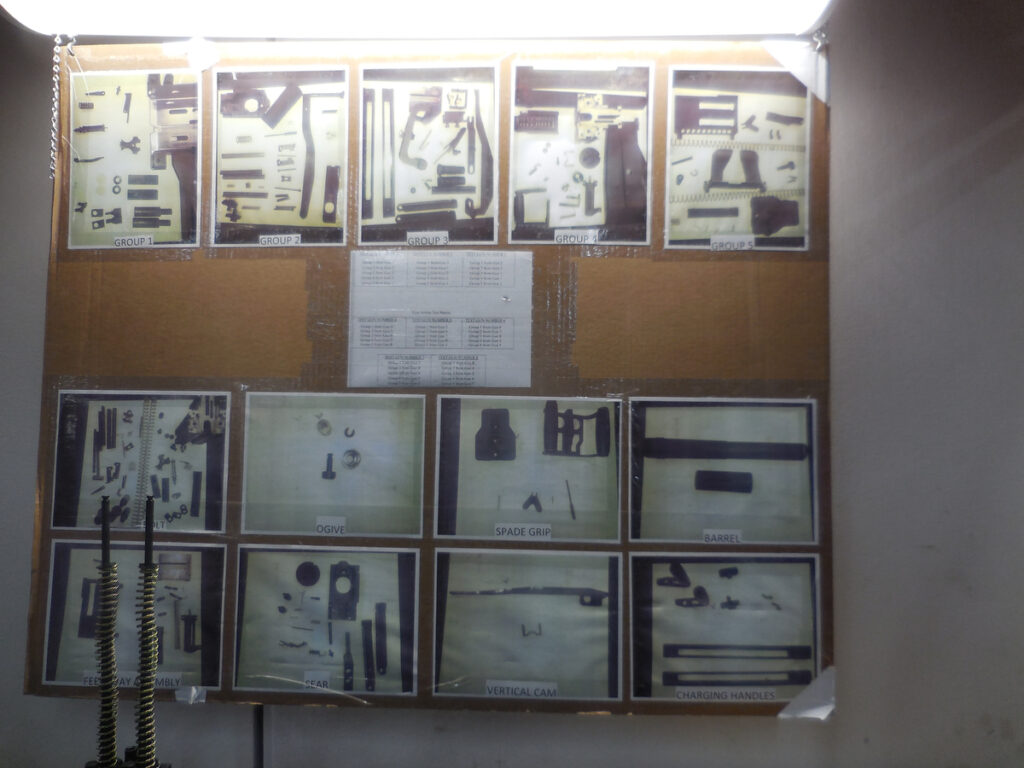

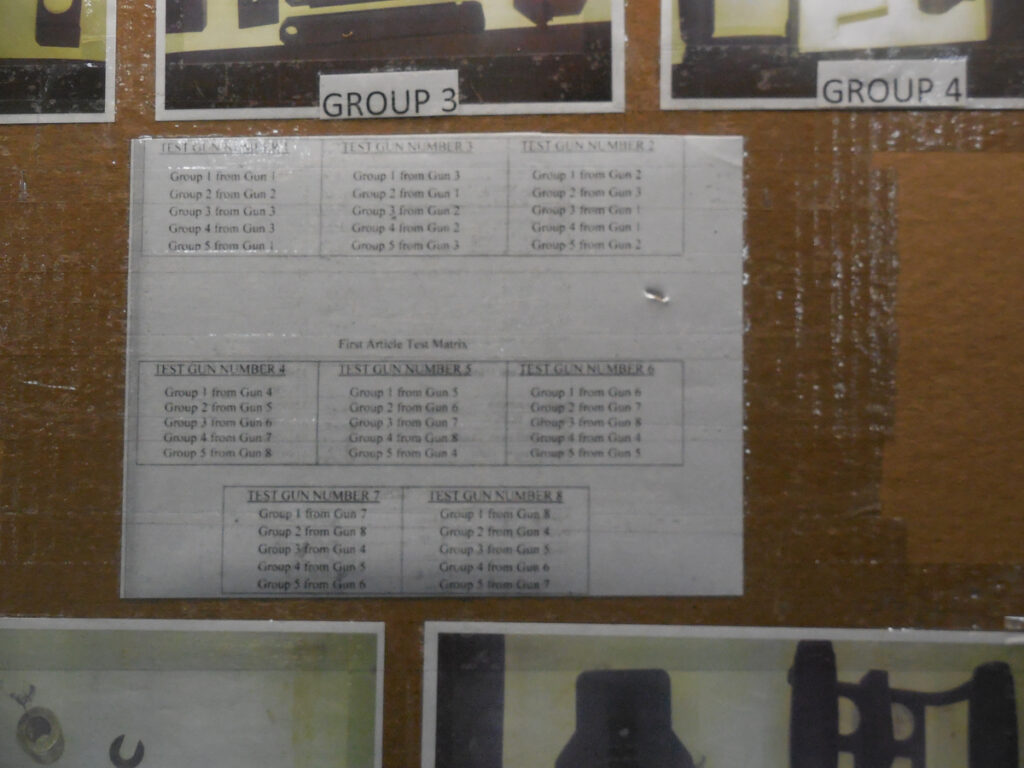

- Interchangeability In the first article we did, we covered some of this, but the further full testing has more of this, and a special station is set up.

- Reliability The longest part of the test, It begins with firing 192 rounds, and repeating it after rounds 152, 2304, 3456, 4608, and 5760. It is a specific cadence, intended to show any dispersion changes, or other issues.

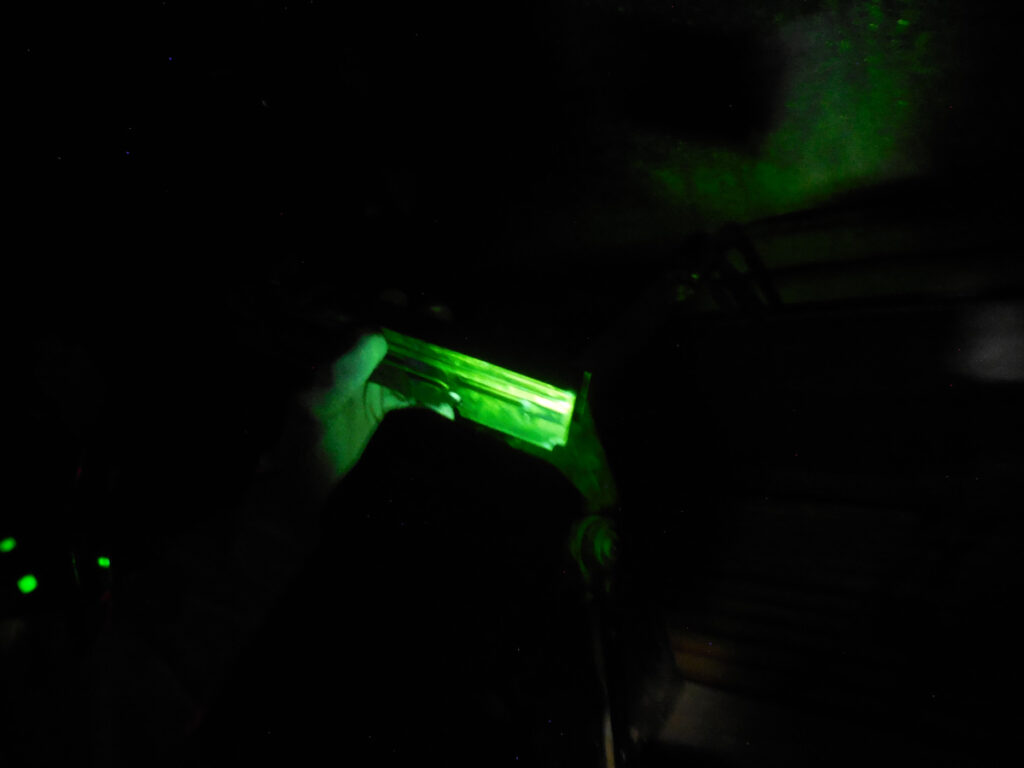

- Full Cleaning and Inspection Specified at every 2,304 rounds. The guns are completely disassembled, visually and magnetic particle inspected, cleaned, and properly lubricated. Parts to lubricate are the bolt, barrel, firing pin cover, firing pin, bolt sear, firing pin sear, receiver, lock plate, and feed tray.

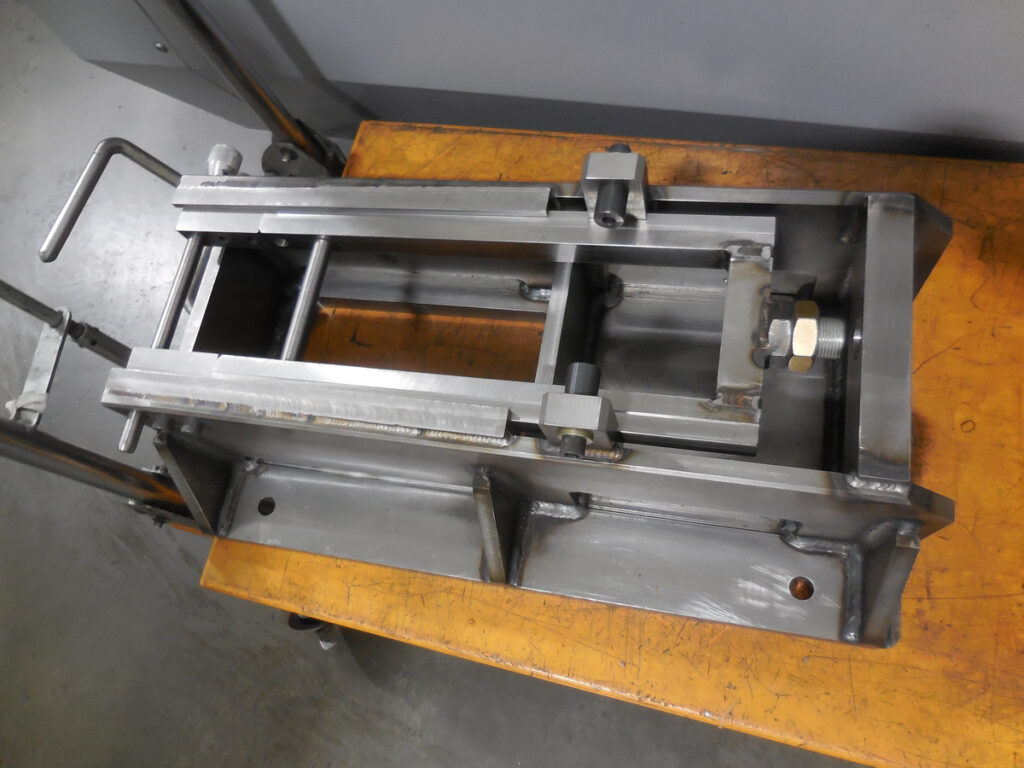

In Section 4.5.8 “Trunnion Load”

- A. For First Article Inspection, this test shall be performed concurrently with the belt pull test.

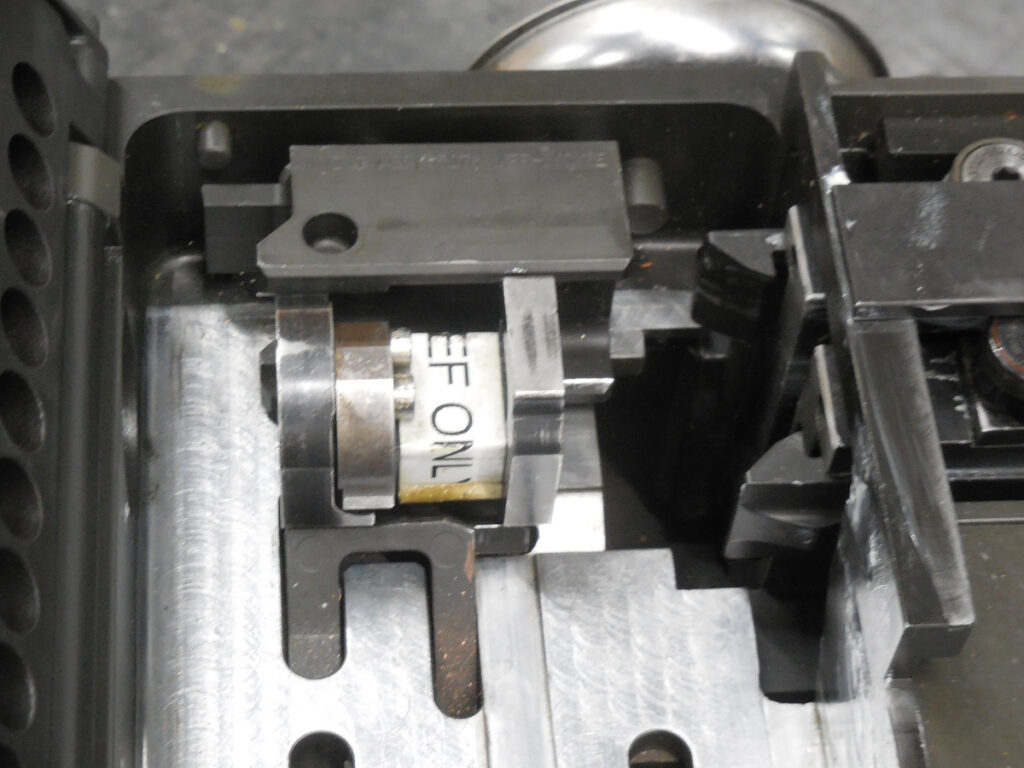

- B. Mount a Quartz Force Link Cell Kistler Model 9362 with a Charge Amplifier Model 504E and a Filter Model 545A (Or Equivalent) directly below the receiver, below the locking pin, integral with the mount and in alignment with the receiver buffers.

- C. Record a time-load trace of recoil using a Honeywell Visicorder Modl 1858 with a TCD (tape compatible differential) Amplifier Model 1887, or approved alternate equipment.

- D. Trunion load forces are to be measured at the mounting point. The last three (3) rounds of the belt fired shall be discounted.

The mount shown here is a special mount custom made to the government specification for the test. The Kistler Force meter is a very expensive and sensitive piece of equipment, yet it is built to handle the recoil forces of larger forces than will be in this test. The reason for testing during the belt-pull test are based on finding variations in the side weight of the belt, and as the belt lightens the forces will change. This data will be valuable to see the consistency of the construction. After this first article test, the trunnion load tests will be less frequent but based purely on the single rounds fired.

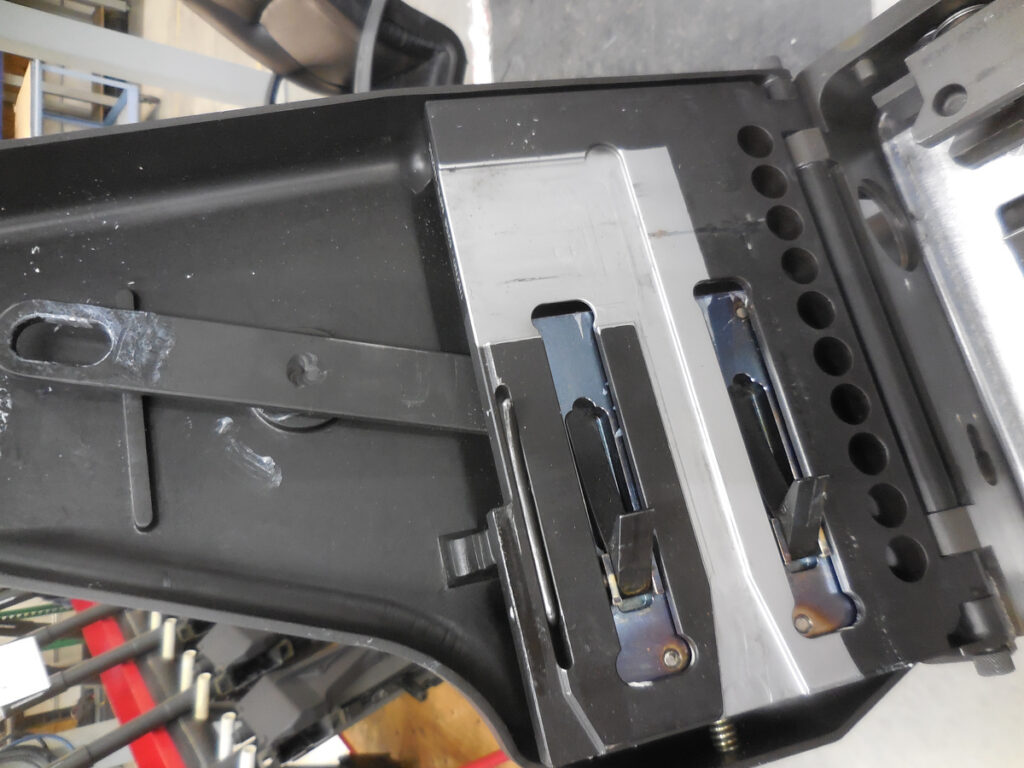

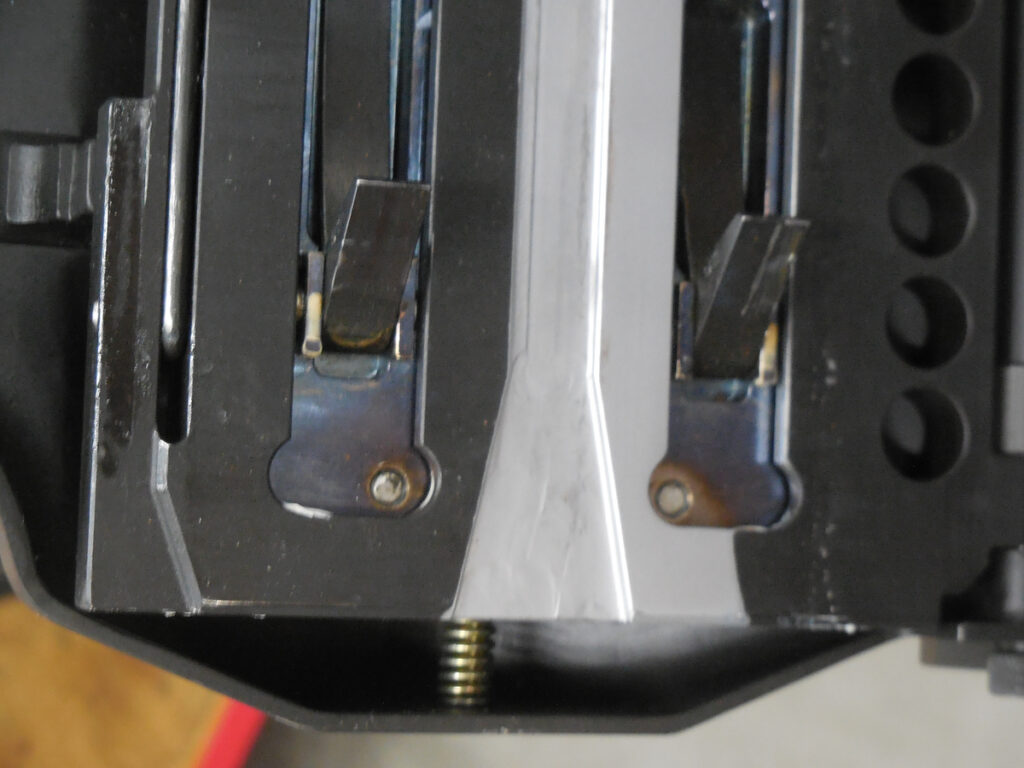

After test-cycling the MK19 with dummy rounds, this is what they look like. Note that the links are de-linked and pushed to the rear. In the closeup, the male and female end of the links are evident.

The male end must be pulled out of the female, to the rear. Thus, when a can of ammunition is first opened, the first round will present with a female end of the link to feed into the feed tray. On cocking, the round is pulled to the rear, then slammed forward into the barrel, pushing the single link rearward on the body of the casing, and ejecting it. When fed into the HK GMG machine gun, because it pushes through forward, the belt must be presented opposite, with the male link into the feed first. This requires taking the belts out of the can before using and reversing the belt.

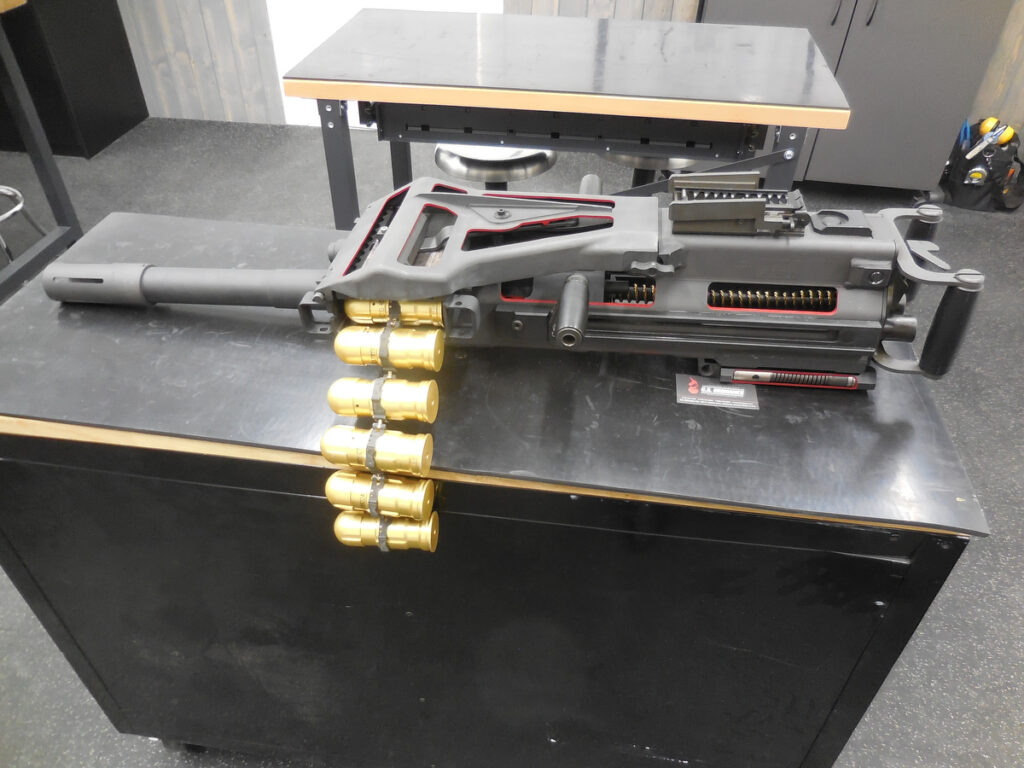

In U.S. Ordnance’s instructor classroom, they’ve made a custom factory cutaway of the MK19 Mod 3 as a training aid. We are curious if these will be available for contract sales.