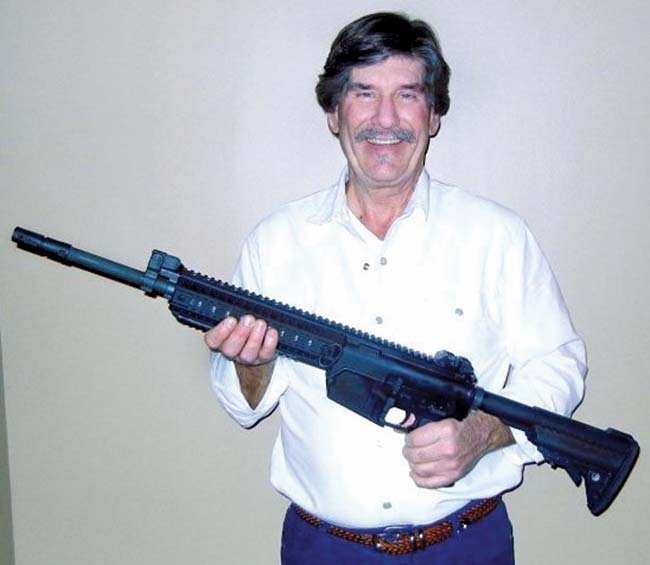

ABOVE: Right side of the Colt LE901 with the Smith Enterprise Vortex flash hider and the folding front sight base.

Most of the Black Rifle manufacturers have both AR-15 and AR10-type rifles in their lineup. This is going back to 1994 when Gene Stoner worked with Reed Knight, Jr. to bring back his AR-10 design from the depths of the scrap heap of U.S. Ordnance where it laid dormant since the early 1960’s. Many companies have come to market with AR-10 type rifles. With all the companies who have produced the 7.62x51mm/.308 Win caliber AR-10, the one you thought would be the first to come out with it pretty much is on the tail end. On February 15, 1959 Colt acquired the rights to both the AR-10 and the AR-15 rifles from ArmaLite. That included all of Gene Stoner’s U.S. Pat. No. 2,951,424. While upon the first payment being made to ArmaLite, Colt began tooling up to produce both variations. However hearing from a representative demonstrating the rifles throughout the world, Colt was told to drop the AR-10 in favor of the AR-15. They felt that is where their market share would be and they did just that. As the years went by the AR-10 drawings disappeared and the idea never resurfaced with Colt. That is not until 2004 when SOCOM announced the SCAR program. This program required modular rifles that were ambidextrous and could have various barrel lengths depending on the operation. They wanted two different models, the 5.56mm SCAR-Light and the 7.62mm SCAR-Heavy.

In 1991, Larry Robbins was hired by Colt as a senior design checker. Oddly enough Larry had no firearms experience at all; his background was electrical electronic packaging but had several contracts as a mechanical design checker on his resume. Larry stayed at Colt through all the tough times, bankruptcy, layoffs and several Presidents. During his time there, Larry worked on the development team for the M16A2, M4/M4A1 and numerous law enforcement programs. Larry received two patents while at Colt. One for a clamp-on gas block and the other for the 4 position fire control group (Safe, Semi, Auto and Burst). Larry went back to college to learn Pro-E engineering software and left Colt for his own contracting ventures.

In March 2004, Larry contacted Mike LaPlante and asked if Colt needed any design help. Mike said yes, they were just gearing up for their SCAR program entries. Colt’s Paul Hochstrate was assigned the SCAR-Light 5.56mm rifle. Larry was tasked with the design of the SCAR-Heavy. By requirement, Colt was to provide actual SCAR-Light guns for competitive testing by SOCOM. The SCAR-Heavy was to be a conceptual/virtual design. As for the M4, it was already “modular.” One could reconfigure the barrel by just removing the existing upper receiver and replacing it with another with the desired barrel length. The normal barrel lengths required were 10.5 and 14.5 inch barrels. The SCAR-H was entirely new, not only to accept the larger 7.62x51mm cartridge but they also wanted different barrel lengths. The design required a modular upper receiver and magazine well. Larry worked on this virtual design and was granted in February of 2006 U.S. Patent Number 2006/0026883 A1 and another in November of 2006 U.S. Patent Number 7,131,228 B2. These two patents were also awarded to two others involved with the development, Paul Hochstrate and Art Daigle. Colt faired very well in the SCAR-Light competition but the winner in the end was FN’s SCAR-Light. It should be duly noted that SOCOM tried for several years to get the FN SCAR-Light to work as needed but due to complication and the excellent performance of the M4A1 and Mk18 rifles, the program was dropped. Larry completed his contract and moved on to another.

From the 2004 to the 2010 time period, Colt was missing out on an entire market being limited to 5.56mm caliber M4 and M16 rifles. Many of their competitors had developed weapon systems where they could provide their customers with 5.56mm rifles and carbines but also a 7.62mm caliber sniper rifle based on the same platform. This of course makes training easy. All your muscle memory remains the same and you are comfortable with how to operate and maintain the system. Many of these companies started showing up at all the U.S. military trade shows as well as foreign military trade shows. Around 2009, Mark Westrom, CEO of ArmaLite participated in early discussions of the SOCOM SCAR-Heavy program. The officials were looking for a weapon to replace the M16/M4 family of weapons with a strong preference in a rifle with an external gas system rather than the Stoner designed internal gas system. Westrom briefed Colt on a version of the original ArmaLite AR-180 rifle, which featured a sliding cylinder mounted to the front sight. His analysis, based on firing tests he conducted while being an Ordnance Officer in Germany, led him to conclude that the external gas system offered no significant advantage over the Stoner system, and indeed suffered a number of technical and logistical disadvantages. He then decided that ArmaLite’s best candidate was in fact the ArmaLite M-15 carbine. Westrom knew that a new system would not be adopted because the Service was certainly not going to replace an existing system with another one varying only slightly. He therefore contacted Colt to suggest that the two firms join in the SCAR program to offer the Colt M4 and the ArmaLite AR-10. At several key military shows, Colt displayed ArmaLite AR-10 rifles with Colt markings. Only about 22 of these rifles were produced. Colt got very favorable reactions from customers on this rifle. It was displayed with a Daniel Defense free floating handguard, Norgon ambidextrous bolt catch and the newly released ArmaLite manufactured forward assist upper receiver, which included a forward assist assembly and various backup sights. Both a rifle and carbine variations were on display.

The reality was Colt wanted their own rifle. In May of 2009, Larry Robbins was coming off another contract and he contacted Paul Hochstrate to see if Colt needed any help in the design group. Colt had suffered a major loss when Mike LaPlante unexpectedly passed away in 2007. The design group knew that Larry had already worked on the modular carbine (SCAR-H) concept but it was not exactly what Colt was looking for. Larry was told that General Keys (then CEO of Colt Defense) wanted a modular carbine that would shoot a 7.62x51mm cartridge but could be easily converted to fire the 5.56mm cartridge. Larry was assigned full time to work on the new modular carbine. Originally an idea was put out to have a helical locking lug configuration on the bolt. Larry worked on that idea for a week or so and determined it was not workable for any number of reasons but mostly because General Keys wanted something to show at the AUSA (Association of the United States Army), which was in October of 2009. Colt had well over 50 years experience with the Melvin Johnson designed multi-lug rotating bolt that Stoner used on his AR-10/AR-15 rifles so he decided to go with an already proven concept. At this time, numerous other manufactures had proven this design including Gene Stoner himself on his newly 1995 introduced SR-25 sniper rifle. Larry started with a basic AR 10 bolt/carrier for his design. He then came up with the idea of offsetting the tail end of the .308 carrier with a 5.56mm bolt carrier. This would keep the lower receiver unchanged for the conversion from one caliber to the other. There is a significant difference in the centerlines of the 7.62mm and the 5.56mm barrels and heights of the magazine when installed in the lower. The SR-25 magazine catch is the same as the M16/M4 at the interface with the magazine. The difference in the magazine between the M4 and the SR-25 determined the barrel height difference and that worked in conjunction with the offset bolt carrier. The tail end had to be shortened to be compatible with the standard M4 receiver extension. This is unique to this model. On many other AR-10 carbines from numerous manufacturers examined by this author, a vast majority use a slightly longer receiver extension. According to Larry, one of the biggest obstacles was the magazine well. It had to be large enough to accommodate the standard AR-10/SR-25 magazine and at the same time small enough to take the 5.56mm magazine. Although not made available to Larry by the design group, another Colt engineer named Kevin Audibert sort of became Larry’s consigliore on many design related issues. When Larry came on as the primary designer, Kevin gave all of his ideas over for Larry to consider. Kevin is a Mechanical Engineer with a BS degree and also has a MBA. Kevin had been with Colt Defense since 2008 and was the primary designer on the Colt entry for the Marine Corps Infantry Automatic Rifle Program. Larry often bounced ideas off of him. Kevin had already been thinking about the magazine design for the modular carbine long before Larry was hired on to design this rifle. Kevin had a good design that needed some tweaking. Kevin’s original concept started with detailed research into other 7.62x51mm magazines on the market including FAL, G3, M14/AR-10 and others. The SR-25 is very similar to the old 20-round 5.56mm magazine and even shared the rib on the back of the magazine. These similarities were the deciding factor in the chosen magazine platform, the SR-25 magazine. The straight up insertion of the SR-25 magazine matched the M4. With this information, Kevin designed an adapter that would fit the SR-25 magazine well and support the M16/M4 magazine using the same magazine and bolt catch for both.

In late June/early July of 2009, Larry completed the virtual design and was ready to present it to General Keys for approval. Upon his approval Larry would get the full backing of Colt to get prototypes built of the rifle. During the presentation, there were many questions but the buck stopped at the General saying when could he shoot one. As previously stated, the General wanted to display this rifle at AUSA and that was less than 3 months away. Following that successful meeting, which moved the project to the next level of building prototypes, Larry went to work on the ambidextrous controls. Unfortunately, Larry’s designs were not used because they were unproven and time was too short and in large part because the rifle had to have as many parts in common with the M4 as possible. So another design ensued. The most difficult to design for Larry was the ambidextrous magazine release. The magazine release had a shaft going across the receiver to the right side. Larry put a lever on the left side to lift the mag catch bar out of its slot. This design went through several iterations to satisfy the configurations for the forging dies. Two former military guys at Colt, Art Daigle and Casimir Pawlowski assisted with the final refined ambidextrous magazine release as seen on the current production rifle. Real world experience is extremely helpful in the design of any military weapon. It is difficult if not impossible to design a battle rifle in an engineering department or model shop without knowing what the guy in the field needs. Without that input at the time of design, when the customer is presented with the rifle, the manufacturer may be in for a lot of cost in redesigning the rifle.

After the presentation to the General, and his approval of the concept, Larry was able to get priority in purchasing, manufacturing, model shop, test and now with design from Kevin Audibert. The program was now on a fast track and the next prototype was in plastic and metal. Colt’s Art Daigle is probably one of the finest model makers in the industry and was invaluable in his ability to produce upper and lower receivers’ solid models and other small parts. The time constraints worked against them on the first prototypes for AUSA. To get a bolt carrier machined in time was impossible, so they cut off a .308 AR-10 bolt carrier front end and machined an eccentric boss on it and cut off a 5.56mm bolt carrier tail end and welded it together. This was much easier said than done. Kevin had been working on a newly designed front sight base due to the larger barrel and gas tube due to it needing to be higher than the standard LE6940 front sight base. Prototype front sight bases were made from billet but production would be cast. By the end of August parts began trickling in and soon Larry had a working prototype. Larry had an incredible opportunity to get some real professional opinions to his design. Some members from a highly regarded Special Operations Force group visited the plant and test fired the prototype rifle. They were duly impressed. There were a few small tweaks made and it went down to the wire but General Keys got two working prototypes shipped out to AUSA. Before Colt could actually show the rifle to anyone, Colt had to apply for a provisional patent to protect the new design.

The rifle made its public debut at SHOT Show 2011. Due to patent issues, the rifle’s receivers were zip tied shut so nobody could open the rifle and examine the spacer for the magazine well and how the bolt carrier was made. These were the two major parts that made this rifle work as intended. The prototypes were tan color. All of the prototypes were selective fire rifles and were designed to be this way with an 11-inch gas system and a 16.1 inch barrel that utilized the Smith Enterprises Vortex flash hider. There were only one or two authors that were permitted to write about the new gun. Larry’s contract was up after the completion of the prototype rifles and he moved on to other things. Colt would further refine the rifle and get a patent application going for the magazine well adapter for the conversion in calibers of the modular rifle. Kevin took over the refinements of the rifle after Larry’s contract was up. Kevin made some modifications to the esthetics of the rifle as well as worked on trying to integrate some standardized M4 parts instead of some of the custom parts Larry designed. But little was changed from Larry’s design. Other minor tweaking was done by Kevin for the forward assist, the front pivot pin as well as rounding off some corners on the left and right side bolt release. Colt would continue to show this rifle at trade show for a couple years prior to actual production. Production of the CM901/LE901 commenced sometime in 2012 and as of this writing is in full production. To the customers’ disappointment, the early rifles did not come with the conversion block and it was not available. They were upset due to the rifle supposedly being a modular rifle but they were not able to use it in that way. Not so long after the first rifle left, Colt began to provide the rifles with the conversion kit that consisted of the magazine well adapter, 5.56mm “H” buffer and action spring. As of this writing, there is a high demand for this rifle and Colt is able to sell as many as they can produce.

Colt has introduced this as a commercial, law enforcement as well as a military weapon, offered in both semiautomatic and selective fire models. Military sales are very small, given the fact this is a brand new weapon without a track record for reliability and accuracy. This will come in time as the rifle gets tested and eventually adopted by foreign customers. It is competing with rifles that already have proven combat records such as the LMT MWS/LM8, Knight’s Armament SR-25, Armalite AR-10, Heckler & Koch 417 and the FN SCAR-H.

The current production rifle is the LE901 16s. The basic rifle is hard coat anodized black. Starting with the lower receiver, the rifle is equipped with the VLTOR Improved Modstock, which is an excellent and durable stock with a rubber anti-slip buttpad. It has two battery storage compartments along with two quick detach mounts. The receiver extension is the standard Mil-Spec carbine 4-position model. As previously mentioned, this is unique to the Colt modular rifle. Most of the manufacturers use a modified longer receiver extension. The buffer is shorter than the standard 5.56mm buffer due to the slightly longer bolt carrier. The lower receiver is manufactured from a 7075 T6 aircraft grade forging. The rifle can be seen with and without an ambidextrous safety selector. The standard pistol grip and trigger guard are used. On the right side of the receiver is an ambidextrous bolt release that is above and behind the magazine release. This is very easy to reach with your trigger finger. The magazine release button is in its traditional place. On the left side of the receiver, the selector is in the normal location along with the bolt catch. The ambidextrous magazine release button is cleverly positioned right in front of the trigger. The button is an arm connected to the magazine release. When the button is pushed the magazine release is lifted out of position to release the magazine. The magazine well is obviously large enough to accept the AR-10/SR-25 magazine. The trigger group is the standard Mil-Spec trigger group. This stands to reason as anyone who purchases a rifle like this is probably going to want to put another trigger in it. There are numerous options out there including Geissele, Timney, JP Enterprises, HPERFIRE, CMC, CMMG, Jewell and Slide Fire to name a few. It is by far better for an OEM to put a basic trigger in and let the customer choose. The trigger on the T&E rifle broke at 8 lbs.

The magazine provided with the T&E rifle is the proven Magpul PMag 20LR. For the most part, when you buy any AR-10 type rifle in the industry, this is the provided magazine. It has without a doubt set the standard for the AR-10/SR-25-type magazine. This particular magazine was a little different. Added to this magazine is a stop notch that prevents the magazine from over-traveling the magazine catch. In speaking with Magpul, this magazine is no longer in production. So it is likely to assume Colt bought a quantity of these but will eventually use the standard PMag 20LR. Quite honestly, this author has used these magazines in rifles for years and never had an (continued on page 108)

(continued from page 39) over-travel issue. I also don’t smack the bottom of the magazine with all my strength to ensure it is engaged either. The LE901 T&E rifle was tested with the Knight’s Armament steel SR-25 magazine as well as the C-Products 20-round steel magazines with no problems.

The 7.62x51mm/.308 Win upper receiver has a continuous top rail. It would not be proper to call this a monolithic upper receiver since mono means one. The bottom rail is removable. There are quad Mil-Std 1913 rails with four quick detach sling mount points – two in the front of the handguard and two at the rear on either side. The receiver has an integrated fired cartridge case deflector and has a forward assist assembly. There is an ejection port dust cover as well. The receiver is manufactured from a single 7075 T6 aircraft grade aluminum forging and is hard coat anodized black. Like all Colt rifles, the inside of the receiver is coated with a dry film lubricant. Additionally, there is a metal insert located in the rear of the cam slot in the upper receiver. This prevents damage to the upper receiver from the carrier bounce mostly associated with piston operated rifles. Colt appears to have applied this to all of their “monolithic rails.” This was first done by Winchester-Western Division during the time period of 27 November 1967 to 27 May 1968 in a project called Modifications of the M16 Rifle Gas System (DAAG25-68-C-0742). Their mandate was to convert the direct gas system to a short stroke tappet piston operation with a conversion kit. They found back then that when trying to integrate a short stroke tappet piston mechanism into a M16 platform that the upper receiver behind the cam slot would get damaged from the bounce of the carrier with the cam pin digging into the receiver. They put a metal screw in place to prevent damage to the receiver and this was a very effective way to deal with the issue. The front pivot pin slot lines up with the forward pivot pin on the lower receiver. The barrel nut requires a special wrench for installation and removal. There is no indexing the barrel nut for the gas tube so the barrel nut can be accurately torqued. The receiver allows the barrel to be fully free floated with numerous ventilation holes to assist in cooling.

The barrel is chambered for the 7.62x51mm cartridge although it is stamped .308 Winchester. The rifling is 1 turn in 12 inches and is 16.1 inches long. Colt also offers a 13 inch barrel as well with the Smith Enterprises Vortex flash suppressor. Like all Colt barrels, the barrel is proof tested with a high pressure cartridge and then magnetic particle inspected to insure against stress fractures. This is a military grade barrel so it is button rifled and chrome plated. Attached to the muzzle is the proven Smith Enterprises Vortex flash suppressor, which has the well earned reputation of being the most effective flash suppressor in the industry. The cast front sight base has a folding front sight and has been updated since in first appeared on the Colt LE6940 rifle. Customer requests came in for a locking mechanism rather than the detent mechanism that was used to engage/disengage the front sight. Colt added a heavy duty lock so it cannot be disengaged by hitting the front sight base on something. The front sight base is pinned in place with two taper pins. This is a very important reliability enhancement for the rifle. This author recently has had two incidents where bolted on front sight bases migrated forward during rapid fire first causing short stroking and then the gas was cut off completely. Pinning the front sight base on prevents this and ensures the front sight base can never move. Additionally, there is a bayonet lug on the button of the front sight base. The bayonet will slide over the Vortex flash suppressor and mount to the bayonet lug. The front sight post is the standard square 4-notch front sight post. Early rifles used the 11 inch gas system but it was later changed to the 9 inch gas system, which is considered a midlength gas system. Much of the reasoning for this came out of feedback from special operations forces who said they wanted a 13 inch barrel. This also permitted the ability to accept a M9 bayonet.

The bolt carrier group is very unique to the Colt Modular Rifle. Due to the requirement of being able to convert the rifle from 7.62mm to 5.56mm, the back end of the bolt had to fit properly into the standard receiver extension spring. As previously stated by Larry Robbins, the bolt carrier is half AR-10 and half AR-15; the front end is AR-10 and the back is AR-15. This design was not only necessary to get the bolt carrier to properly align with the receiver extension but also to actuate the firing mechanism, including the hammer to properly strike the firing pin, but also to function the automatic sear. The bottom of the carrier is modified to allow for the magazine to be inserted with the full capacity. The bottom of the bolt carrier is somewhat triangular in nature allowing the rounds to sit up farther taking some spring tension off of the magazine spring. The firing pin has the addition of a spring that assists when using match ammunition with a standard nonmilitary primer. Standard primers are softer than the military and the spring gives a little insurance against a slam fire (firing pin detonating the primer due to the inertia of the bolt carrier moving forward) when using soft primers. The bolt was modified to accept the new heavier extractor. Early endurance testing showed that the extractor was prone to failure within 3,000 or so rounds. The extractor had to be modified to cope with this issue to extend the service life of this component and the bolt had to be modified to accept the redesigned extractor. The breechface depth was slightly increased. The extractor pin was modified so it would only go in one way. There was a larger head on one side and the hole in the bolt was countersunk on one end. All of these modification caused incompatibility with industry standard bolts, extractors, extractor pins and firing pins making the LE901 bolt and firing pin proprietary components to Colt. Like all Colt bolts, the bolt is proof tested with a 67,500 psi high pressure cartridge and then magnetic particle inspected to ensure against stress fractures. The extractor pin has been redesigned as well having one end larger than the other. This way there is only one way to insert the extractor pin also this is easier to make sure the pin is flush with the bolt. The initial extraction problems were found with the early 11 inch gas system with breakage of the extractor after relatively few thousand rounds. However, with the change to the 9-inch gas system, this extraction improvement became a key to reliability due to higher cyclic rate.

The rifle has an overall length of 34 inches with the stock retracted and 37.25 inches with the stock extended with the standard 16.1 inch barrel. The rifle weighs 9.4 pounds unloaded. With standard 7.62x51mm NATO ammunition, the 16.1 inch barrel gets a muzzle velocity of 2,770 feet per second and with the 13 inch barrel 2,540 feet per second. The rifle can be had with a selector of semi-auto only or selective fire with full automatic or 3 round burst.

To convert the rifle from a 7.62x51mm to 5.56mm is very simple. First, you separate the receivers. Remove the 7.62mm buffer and action spring and replace it with the standard M4 action spring and “H” buffer. The magazine well adapter has a detent pin: insert the front lug of the standard 5.56mm upper receiver into the front of the magazine well adapter and close the pin to detent. Now slide the magazine well adapter into the top of the magazine well until the receivers are flush and push in the front pivot pin to detent. Now push inward on the rear takedown pin locking the receivers in place. This is all there is to it. The additional length of the lower receiver compared to the standard M4 is approximately 1.3 inches in length. The receiver used to test fire the T&E rifle was a standard Colt LE6920 upper receiver equipped with a Knight’s Armament RAS System.

Initial testing was conducted with Black Hills 7.62mm 175gr OTM, Winchester USA 7.62x51mm NATO and Hornady 168gr OTM ammunition. The weather was 3°F with a wind chill of -15°F. The first ammunition used was the Hornady. The first two rounds short stroked in the rifle. After the rifle warmed up, there were no malfunctions in the 200 rounds fired. The expected culprit was the ammunition had some stability issues in the extreme cold weather as the ammunition had been sitting outside for a couple hours prior to shooting. The other two are military grade ammunition and worked flawlessly. The optic chosen was a Leupold Mark 4 LR/T 3.5-10x40mm Matte, M3 Illumination reticle scope (67950) optic. The best group of the day was with the Black Hills 175gr OTM (M118LR) at 100 yards the group was 1.2 inches. Under better conditions, perhaps the group would have been better but it was cold!

The rifle was now reconfigured to fire 5.56mm. The LE6920 upper was placed on the adapter and then into the rifle. More than 500 rounds were fired through various magazines including the Surefire 60-round magazine, Hera Arms H3, Magpul PMag, H&K steel and translucent magazines, Lancer AWM and Troy Battle Mag with no malfunctions of any kind. The ammunition used was Federal XM193, 55gr full metal jacket. The shooting was conducted at 25 yards off hand.

When comparing the modular rifle configured in 5.56mm to the standard LE6920 there was really not that much of a difference in feel. The lower receiver was slightly longer but it had little bearing on the feel and balance of the gun. The modular rifle concept is sound and it does as designed and advertised. Is there a requirement or military need for such a weapon? That is up to the military customer. The rifle is an ideal combat rifle in 7.62x51mm for a soldier in the mountains of Afghanistan. As far as mission adaptability to 5.56mm, it is assumed a special operations unit will know their environment to determine their gear. If they are to be in a close quarters environment they would probably just take a M4A1 or a Mk18. If they know they will be in an area where they will need long range it would be assumed they would go for the LE901. It is obvious they would not carry a spare upper and magazines with them in the field. They would have the weapon in one configuration. This rifle will by far have far more of a future as a 7.62mm rifle than a 5.56mm. The LE901 is a top quality rifle, what you would expect from Colt. The rifle was released later than the consumer would have wanted but Colt, throughout the last 60+ years, has never put a new product on the market without proper testing to insure the rifle was ready to be put into production. With the rifle being so new to the market, only time will tell where its true niche will be found. It has entered the military market a little late in the game and will compete with rifles with several years of combat service. It will have to prove itself the same way as the M4 did – on the battlefield.