ABOVE: CZ Engineer Martin Sanda puts rounds downrange and brass in the air during the test of the 5.56x45mm CZ 807 AI assault rifle, using a benchrest bipod and Meopta’s “MeoTac” 3-13×50 sniper scope. Photo courtesy CZ.

CZ is an old and highly respected firearms manufacturing company located in the Czech Republic. SADJ is certain our readers are familiar with the many military and civilian products that they have produced over the years; the ZB-26 light machine gun which became the British Bren; the famous CZ 75 handgun, as well as many fine sporting and hunting firearms. We were delighted to have the opportunity to visit the Bzenec Shooting Range and to spend some serious time testing the current version of the BREN series of modern assault rifles. We would like to thank Military Product Engineer Martin Sanda, Gunsmith Pavel Vrága, Sniper Petr Marek, Project Manager David Kreisl, Media Liaison Manager Hana Smilkova and Promotion Manager Jiri Sedlacik among others for their assistance in this endeavor, they made it possible.

Late June, 2015 – Uhersky Brod is located about 300 kilometers southeast of Prague, in the beautiful Zlin forest regions of the Czech Republic. It was easier to fly into Vienna, Austria and drive to the town, than to come down from Prague, and the scenery was breathtaking on the trip. The original “CZ” firearms manufacturing company known as Ceská zbrojovka was re-formed into Ceská zbrojovka a.s. in 1992.

The introduction of the new style of assault rifle – the CZ 805 BREN – using lightweight alloys and polymers with special characteristics, has led to a new contract to outfit the Czech Army. That program is going well, and CZ is actively pursuing new frontiers for this new style of product. “I” is for “India”

While the CZ 807 series of rifle is an extension of the CZ 805 assault rifle design, there are specific customers in mind for the 807 series. Two customers that CZ is working with are New Zealand (Thus the “NZ” in the serial numbers) and India. Each has specific characteristics that the customers want. The trials in New Zealand required several barrel lengths, about half with 14” and the other half with 16” barrels. The Indian requirement was for 16” only.

It was the Indian requirement for over 65,000 new rifles that initially led to this test, and dictated some of the details. However, the CZ 807 A has a broad appeal to many other customers. The now dormant Indian solicitation included a very difficult requirement that both 5.56x45mm, and a change to 7.62x39mm be available to the soldiers. The Indian Army has been using their indigenous INSAS 5.56x45mm AK based rifles with many reported problems, while many of their soldiers also use AKMs in 7.62x39mm for various situations. Thus, the dual caliber change-out requirement. At SADJ, we’re not convinced that this broad a paintbrush need be used to solve that issue; perhaps the Indian Army might be better served by homogenizing their service caliber to one or the other- The CZ 807 could certainly satisfy either choice they made and simplify the Army’s logistics. Nonetheless, what the customer wants is what the vendors strive to provide, and the CZ 807 series of dual caliber is an outstanding contender.

The Gauntlet

When CZ contacted SADJ to organize a Mil-Spec test, this dual caliber situation had to be taken into account. We were aware that the CZ 805 series had undergone many military style tests, in many environments, and had performed exceptionally. There had been tests where massive amounts of ammunition- in the tens of thousands of rounds- had been expended very rapidly. Gossip from the testers involved spoke of high heat (Of course) at these high rates of fire, with the weapons just keeping on firing with little to no problems. While this sounds outstanding to a fighter, it does not provide quantifiable data that a procurement person could use. CZ was asking SADJ to provide a proving ground where not only would the CZ 807 face what Special Operations fighters are looking for answers on, but what do the procurement people, the logistics people who must prepare an army for such a major change, want to know.

The Gauntlet was thrown down, and it was just the kind of thing that we at SADJ knew we were up for.

Our proposed test was for two rifles, one of each caliber, each firing 12,000 rounds. We wanted the following answers for CZ’s customers:

1- Is the CZ 807 AI up to Mil-Spec?

2- Will it perform through a US style Mil-Spec test?

3- Are the parts interchangeable for full function testing?

4- What are the Mean Rounds Between Failures?

5- What is the barrel life and how is the dispersion testing?

6- Can we ascertain that both the logistics groups and the end users will be satisfied with the weapon system?

SADJ could ascertain the Mil-Spec issues and caliber interchange very easily with a properly designed test. Barrel life and dispersion are more related to how that test is performed- leading to the most crucial questions we had to design the test for- elaborated in number 6 above.

Most end users intuitively consider the famous four qualities in firearms that the likes of Eugene Stoner, L. James Sullivan, Reed Knight and many others have polished over the years; is the weapon design Simple, Reliable, Accurate, and Robust? If it doesn’t meet those requirements, it’s hard to get it accepted by the professionals who have to use it. Most end users will look at how reliable it is, and ask whether it can it withstand heavy use- long bursts while they provide cover, “mad minutes” in tough firefights? All questions that when answered, provide confidence and comfort for the warrior who has the weapon as a life-saving or life-taking tool.

Logistics personnel have a different requirement in mind- it’s not all combat, it’s mostly about training sessions, longevity, chain of supply, and cost accounting. The planned purchase of a new weapon system requires many factors be taken into account- and SADJ had to design a test that could answer these questions as well.

The tests were designed to answer these questions in a proficient and comprehensive manner. We invite our readers to understand that while this type of test sounds like fun, it is in fact a grueling and demanding task- many hours and many people working to keep the details in order to not invalidate the terms of the test. (Imagine yourself, excited to partake in a 30,000 round handgun live fire test, then discovering that someone has to LOAD all of those magazines, and it’s going to be YOU). It was decided that the best way to proceed was for the factory to provide the firearms, the ammunition, the shooters and technicians and the range, and this author would be in a supervisory capacity to ensure protocols and temperatures were adhered to, and perhaps do some of the test firing.

In order to speed up the testing time, and allow a natural test of barrel erosion and dispersion, CZ provided an air compressor with hose to cool the barrels. It’s important to “Rest” the barrels and return them to an agreed ambient temperature between each firing. For those who want to engage in this type of test, dropping weapons in water or using other methods that cool too rapidly are not effective in getting true results. The need is to simulate years of training interspersed with long periods of no use, not to wow a crowd with clouds of steam. Ambient temperature air sent through the barrels at perhaps 100psi will speed up the removal of heat, and shorten your testing time without compromising the barrels. If you do this type of testing a lot, then remember that compressors mean moisture and add some condensing to the system.

We utilized one shooter at a time, alternating rifles to allow for the cooling period.

Some of the details of what we arranged for the test firing protocol changed as we discussed the on-going tests with CZ and their engineers. Essentially, they were confident that the temperature on the barrels could go higher than our first recommendation of taking the temperature down to around 80° F before returning to firing. Their engineer felt very strongly on two subjects- first, that we could fire faster than our test protocol, and second, that he did not want any mandatory parts changes- just inspections at the prescribed points. Having run similar tests in other conditions, he was confident in his product. So, we ran the first part of our tests at the prescribed rates, and as SADJ saw the performance of the weapons was superior, we switched the firing rates up, and did away with parts changes.

Days at the Range

A total of 24,000 rounds would be expended, 12,000 of each caliber, and only one rifle in each caliber would perform this. Each day, the temperature was around 77-80 degrees Fahrenheit, or 24 degrees Centigrade. It did not rain, and the humidity was average. Nice days for testers and testing alike.

The firing sequence would be 90 rounds at semi-automatic for the first rifle, fired 12 rounds per minute. That is an excruciating 5 second wait between firing.

Then, 60 rounds at fully automatic, fired in 5 round bursts with 5 second intervals.

The rifles are switched, and the temperature of the first rifle has the barrel brought down to 80-100 Degrees F before it is returned to the line.

At approximately 600 rounds per rifle, SADJ was satisfied that the cooling periods were longer than necessary, and the CZ engineer’s desire to speed up the testing would work well and not skew the results from the point of view of

procurement personnel.

The firing sequence would be 90 rounds at semi-automatic for the first rifle, fired 20 rounds per minute. That is a 3 second wait between firing.

Then, 60 rounds at fully automatic, fired in 5-7 round bursts with 3 second intervals.

The rifles are switched, and the temperature of the first rifle has the barrel brought down to 120 Degrees F before it is returned to the line.

We continued with this regimen until approximately round 8000 for each rifle, when we stepped up the pace to 90 rounds at semi-automatic fired 40 rounds per minute, then, 60 rounds at fully automatic, fired in 5 round bursts with 2 second intervals. Heat issues at this point were reaching the limits of what the procurement part of the test required, but the rifles showed no negative signs whatsoever.

Hasty Defense

The last 5 magazines that we fired were at full cyclic rate- approximately 800 rounds per minute. This was in keeping with the US military’s new “Hasty Defense” test. No problems were encountered other than one double feed that was magazine related. Temperatures on the gas port block, which had been between 450 and 600 degrees F for most of the testing, approached 780 degrees F. High, but not scary high for what the rifles were doing.

Mean Rounds Between Stoppages (MRBS) is determined by dividing the total number of rounds fired by the total number of stoppages. “A stoppage is defined as any unplanned cessation in firing or the inability to commence or cease firing attributable to the gun. All incidents shall be recorded and any considered as not chargeable to the machine gun shall be substantiated by the contractor.” During testing on the CZ 807 AI, we had (4) total stoppages that were properly attributed to the ammunition. Ammunition issues (failure of ammunition) do not count in this type of test. We had one stoppage attributable to a magazine failure to feed, and one extractor issue. The math on that is: 12,000/2=6,000. That’s “6,000 Mean Rounds Between Stoppages.”

Mean Rounds Between Failures (MRBF). MRBF is determined by dividing the total number of rounds fired by the total number of failures. “A failure is defined as any stoppage which involves part replacement or requires in excess of one minute to correct; or involves any failed or damaged part detected during scheduled preventive maintenance, the replacement of which is not authorized at the crew or organizational level of maintenance as prescribed by Source Maintenance Recoverability Code and TM-9-1005-313-23P.”

The MRBF numbers are the same as for Stoppages, we had only one issue with an extractor that needed changing on the 5.56x45mm rifle. This was a very impressive 6,000 rounds. We had no real failures whatsoever that were related to the firearms parts.

To be clear, the US M4A1 Rifle Mil-Spec test specifications require better than 600 MRBS and 3600 MRBF for performance. The CZ 807 AI clearly performed well above those standards.

CZ 807 A Series

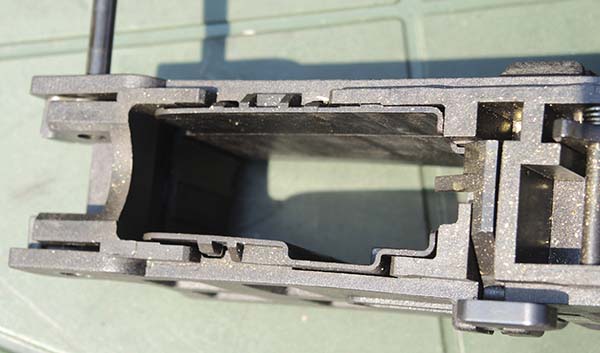

The 807 series is derived from the CZ 805 BREN series of rifles. The basic characteristics of the rifle are that it is a piston operated, gas-driven select-fire rifle of dual calibers. The ambidextrous charging handle is easy to change sides on. It has a modular design, with an aluminum alloy upper receiver and a polymer lower receiver/fire control group. The bolt is a multi-lug type riding in a bolt carrier, locking into a barrel extension. The system is balanced well, and designed to meet the most rigorous modern requirements of an assault rifle.