ABOVE: Advantages of caseless ammunition; the rounds are lighter in weight and less expensive to manufacture. Disadvantages include a problem clearing malfunctions and delicate nature of the solid propellant. (Springfield Armory Historic Site)

During the early spring of 1966, the U.S. Navy Department contacted Smith & Wesson representative Mr. George Ersham to inquire about the possibility of the U.S. Corporation designing and manufacturing a weapon that would be similar in concept and operation to the Swedish K. By the fall of 1966, the Development Section of Smith & Wesson received an official written request from the Department of the Navy for the development of a new 9mm submachine gun. Corporation officials met with SEAL Team One at the Naval Amphibious Base Coronado in San Diego, California, to discuss the project. During the meeting Smith & Wesson officials were provided with a list of the characteristics desired in the proposed submachine gun:

- Need is urgent

- Reliable

- Rugged

- Select-fire operation

- Cost-effective

- Ease of maintenance

- Magazine capacity of 36 rounds

- Cyclic rate of 600-800 rounds per minute

Mr. Dwayne Charron of the Research and Development Section of Smith & Wesson was chosen to head up the project. Mr. Charron was well-qualified for the task, having a lot of experience with the development and design of many of the company’s firearms. S&W issued the number 76 as the model designation for the project, simply as a control number, having no other significance.

Although the exact number of S&W submachine guns procured by the Navy is unknown, the total was believed to be limited. When Smith & Wesson discontinued manufacture of the Model 76 in July 1974, it presented a problem for the Navy in obtaining spare parts necessary to maintain the weapons. By late 1982, the Mark 24 Mod 0 (the Model 76) was phased out of the Navy inventory. The Smith & Wesson Model 76 was eventually replaced by the Heckler & Koch 9mm MP5.

Caseless Ammunition Program

The research and development for a suitable caseless cartridge has been ongoing for years. A successful design has yet to be developed. Several foreign and domestic cartridge and firearms manufacturers as well as the U.S. government have initiated programs to develop and perfect the caseless round, only to achieve limited success.

A successful caseless round would provide many advantages over conventional ammunition. The caseless cartridges would be smaller and lighter, allowing soldiers to carry a larger ammunition load. The mechanisms of firearms could be made much simpler by eliminating many parts like firing pins, extractors and ejectors. One of the disadvantages was the problem of clearing misfires. One rather low-tech means is to use a cleaning rod to push the defective round out of the chamber.

The original caseless cartridge concept can be traced back to Smith & Wesson with their Volcanic Cartridge, patent number 14147, dated January 22, 1856. The cartridges consisted of a conical lead projectile with a hollow base. The base was filled with propellant, which was held in place by a cork or brass base. The mixture was ignited by a separate primer, propelling the projectile out of the barrel. Although the Volcanic Cartridge was not successful, it did eventually lead to the partnership of Horace Smith and Daniel B. Wesson. Since that era, there have numerous attempts to perfect a caseless cartridge. During World War II the Germans experimented with a caseless 7.92mm rifle and machine gun ammunition, but their attempts were largely unsuccessful. The U.S. Army had attempted to convert an M14 rifle to use a caseless 7.62mm NATO cartridge. Most of the work was carried out at the Frankford Arsenal. Insurmountable problems and lack of funds forced the Army to abandon the program.

It was not until 120 years after the Volcanic Cartridge that the engineers at Smith & Wesson would again attempt to perfect a caseless round. Development was initiated during November 1966. The key personnel assigned to the project were Chief of Research and Development, Dwayne Charron, Harold E. Sibley, a research engineer and an Austrian inventor, Hubert Usel. Mr. Usel ran an electro-chemical research laboratory in Inzing, Austria, where he had been developing caseless ammunition for several years. He was hired by Smith & Wesson in 1966 to assist in their caseless project.

Smith & Wesson’s parent company, the Bangor Punta Group, owned a company called EXPLO in Lorena, Brazil, that manufactured explosives. The factory had a well-equipped laboratory and other facilities to (discreetly) develop a caseless cartridge. The 9mm bullets used were manufactured by CBC Global Ammunition–Magtech of Brazil and modified at EXPLO.

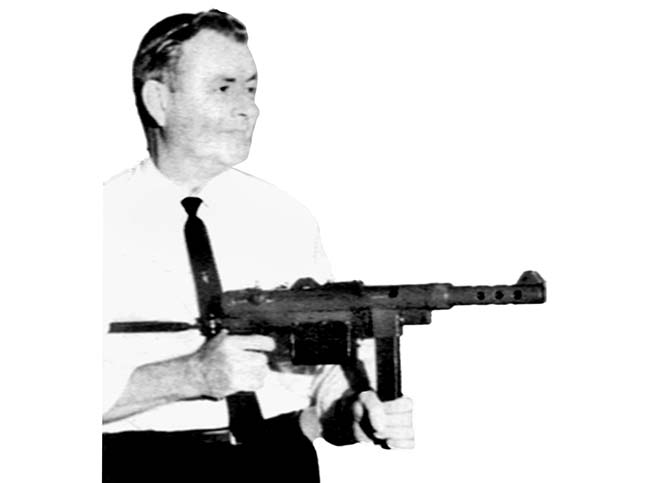

The first weapon for caseless ammunition experimentation by S&W was the venerable Swedish K 9mm submachine gun equipped with a battery box with a sliding on-off switch. Supplying electrical power from a magneto was attempted, but a battery had proven more reliable. More than 50,000 rounds were fired through the prototype without a battery replacement. Eventually, the emphasis was shifted to developing the Smith & Wesson Model 76 submachine gun to use caseless ammunition.

The S&W 9mm caseless round was slightly over an inch in length; it used a standard 9mm .355-inch diameter, 124-grain projectile with a stud at the base. The propellant was a solid mass that was attached to the base of the bullet. The stud that extended from the projectile’s base was designed to give additional mechanical strength to the propellant compound. The solid propellant was covered with a protective coating that served to provide some resilience to water and heat. Producing a suitable coating to effectively protect the propellant was one of the problems encountered during the caseless ammunition program. The Smith & Wesson caseless cartridge employed a primer that was activated by an electric charge. The small disk of priming composition was very thin and attached to the back of the solid propellant; the primer was insensitive to percussion. Upon firing, the primer and propellant were completely consumed. The muzzle velocity of the 9mm caseless round was the same as a conventional 9mm cartridge. The caseless round was 30-percent lighter than an equivalent conventional cartridge.

Two Smith & Wesson submachine guns X186 and X219 were adapted to fire caseless 9mm ammunition by the addition of a Burgess 30-volt, U20 dry-cell photoflash battery inside a battery box mounted just forward of the trigger guard. The weapon was configured so that the cartridge could not be ignited unless the bolt was completely in the forward position. The chamber of the barrel was considerably longer than the cartridge itself. The front of the breech bolt provided a tight seal giving the necessary obturation to allow the burning propellant to build sufficient pressure to launch the bullet. A pair of electrodes was mounted inside of the bolt to provide an ignition source. The power was transmitted to the electrodes by a switch, which also acted as a safety. There was no firing pin or extractor on the bolt. A conventional box magazine was used to feed the cartridges. Reportedly, there was less recoil than found on the Model 76 that fired conventional 9mm ammunition.

The first public demonstration of the caseless Smith & Wesson Model 76 submachine gun was held on November 2, 1967, at a firing range near Lodi, New Jersey. The many newspaper reporters attending the demonstration were told by company representatives that the caseless ammunition concept was the biggest advance in firearms technology since the invention of metallic cartridges cases—which rendered previous muzzle-loaded weapons obsolete. Development of the new caseless rounds was the company’s first venture into the ammunition field.

The Smith & Wesson Company and the Model 76 submachine gun received a lot of press coverage and publicity from the caseless ammunition program, with articles appearing in virtually every gun-oriented publication of the day. Eventually, the caseless program was shelved. The fragility of the rounds and the inability to stand up to the elements were just a few of the reasons for the cancellation of the project. Despite the best efforts to solve the problems, the caseless ammunition was unsuited for a military environment.

Special thanks to Curator Alex MacKenzie and the entire staff at the Springfield Armory National Historic Site.