Every so often a product comes along that is completely, unequivocally “new.” Not just a new variation on an old design, or a new design of an existing technology, but really, truly new. Savannah, Georgia-based PolyCase Ammunition’s ARX® projectile, featuring three highly-engineered grooves on the ogive of the bullet, is that kind of product. Everything from the raw materials, to the manufacturing process, to the mechanical function of this bullet is new, and once you understand the way it works and its intended use, it becomes clear that the ARX is the harbinger of a revolution in small-arms ammunition.

The ARX is a metal-polymer, injection-molded bullet that employs fluid dynamic principles to impart energy to soft-tissue targets. Let’s unpack that statement one part at a time:

Throw out your assumptions about lead cores and copper jackets being necessary to create bullets with high terminal effectiveness. The ARX is a monolithic (read: no core or jacket, it’s solid throughout) bullet made from a high-tech metal-polymer matrix. The raw material creates a bullet that doesn’t fit cleanly into any existing category such as FMJ or frangible. It’s tougher than the frangibles on the market – it will penetrate soft-tissue and heavy clothing with no fragmentation – and yet it retains the low-ricochet benefits of a frangible ideal for short-range combat, naval security operations, and urban warfare applications.

The metal-polymer matrix is formed into a bullet by injection molding. Injection-molding technology is being leveraged in a very unique way when it comes to the ARX. The shape of the ARX, a “fluted” bullet (more on this in a moment), could theoretically be achieved by machining. But the efficiency gains of injection molding allow the ARX to compete on price with mainstream JHP bullets on the market, as opposed to the much pricier “specialty” bullets out there.

All of this new technology combines to create an entirely new shape of bullet – the “fluted” design we mentioned above. The grooves on the ARX bullet serve to compress and pressurize soft-tissue before ejecting it laterally at a 60-90 degree angle perpendicular to the bullet’s forward trajectory. This fluid redirection is an incredibly effective energy-transfer mechanism; more effective than friction alone, which is the primary energy transfer process for hollow-point bullets. The fact that unlike a hollow-point this bullet does not need to mechanically transform in order to dump its energy into a soft-tissue target means one less variable in a high-speed, high-intensity combat situation. That’s always a net-positive from the operator’s standpoint. The result is a new bullet doing things in new ways, which in our opinion could fill a very interesting niche in the fields of short range combat, naval operations, and urban warfare.

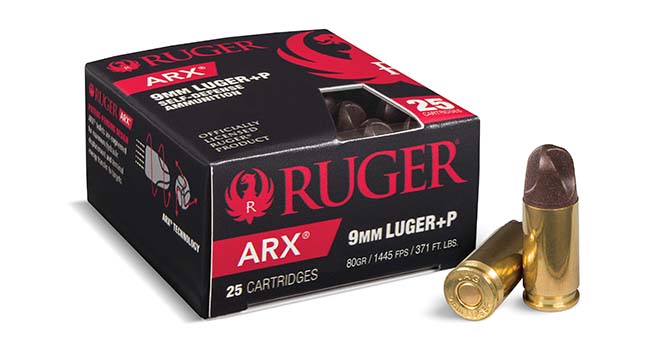

The PolyCase ARX bullet is currently marketed and sold under the Inceptor® and Ruger® brands, and is available in .380 Auto, 9mm Luger, .38 Special, 40 S&W, .45 Auto, .458 SOCOM, and .50 Beowulf.