ABOVE: Col. Michael Manning (L), Marine Corps Systems Command’s program manager for Infantry Weapons Systems, congratulates Salvatore Fanelli (R) on winning the Donald Roebling Award.

In 1982 I had just accepted a job to run the engineering department at FN Manufacturing, Inc. where the M240 machine gun would be produced for the first time in the U.S. My first job was to hire some engineers to assist me, and my very first interview was with Sal Fanelli, a young engineer out of Remington. It didn’t take me long to figure out Sal really understood firearms and that I wanted him on my team. I hired him on the spot. Through the years we enjoyed many successes together, getting new machine guns, systems, and accessories type classified in the military. In 2000, Sal was awarded the George M. Chinn Award for his contributions to the small arms industry. Presently, Sal is a supervisory engineer for Infantry Weapons Systems at the Marine Corps Systems Command. I recently learned the Marines had awarded Sal the Donald Roebling Award for acquisition. Sal led the charge in acquiring a new 5.56mm combat round for the USMC. I caught up with Sal recently to find out more about the new round and his role in the acquisition.

Why did the USMC decide they needed a new round of 5.56mm ammunition?

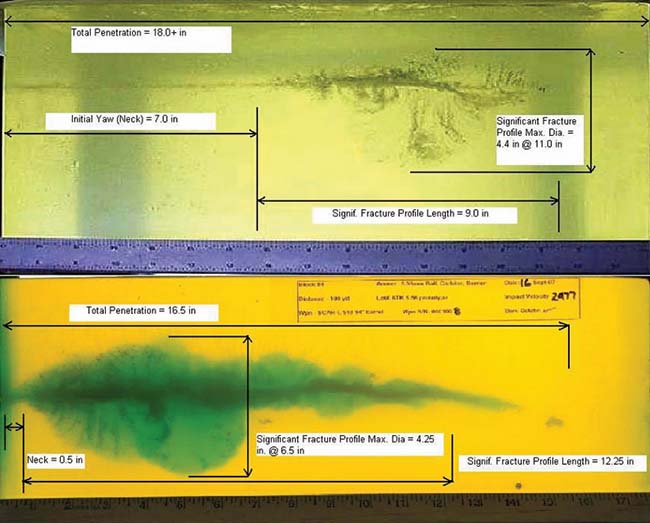

USMC determined that the performance of the M855 was inconsistent. Firing into a block of ballistic gelatin, we determined the M855 had yaw dependency. What we mean by that is from high speed videos of one round from an M4 we observed the path of the projectile doing exactly what we expected. It provided adequate terminal effects, but this didn’t happen every time. Other rounds went straight into the block and straight out of the block – no yaw, no enhanced terminal effects. We considered this inconsistent performance and confirmed that the M855 was impact yaw dependent.

We needed a round that gave consistent terminal effects from round to round, ammo lot to ammo lot and gave the exact terminal effects every time. We needed this performance at ranges from 0 to 400m.

You mentioned that the bullet went straight through. Was there a cause you could determine or was it just pure inconsistency?

From one round to the next, the terminal effects were not consistent. We determined it wasn’t due to being the first shot out of the gun, a cold barrel or a hot barrel, or anything else. It was so random it had to be the ammo.

It was through extensive testing that we saw these inconsistent effects and we couldn’t live with them. We wanted a term to describe this inconsistent phenomenon. That’s when the Marine Corps accepted the term “blind to barriers” suggested by Supervisory Special Agent Buford Boone, Supervisor of the FBI’s Ballistics Research facility and Hays Parks, a senior lawyer in the Office of General Counsel, DOD. Our new round would be blind to impact yaw and blind to barriers. That means it would not matter at what angle the projectile entered the gelatin block. It would give the same performance every time. At the same time we needed a round that went through intermediate barriers, like car glass, or a door, or clothing and did not ricochet or deviate from the shot line. The new round was to defeat the barriers and continue to do what it was supposed to do as far as terminal effects.

While you were looking for a new round, was the Army’s M855A1 improved 5.56mm ammunition in consideration?

No, it wasn’t around – at least as far as we knew. Later we found out the Army was quietly developing a new 5.56mm round but was so quiet about it the other services were not aware. So, we put a “sources sought” announcement out to industry to let ammunition manufacturers know we were in the market for a new 5.56mm round. The new round had to be designed so it would give us consistent results.

We did have an ulterior motive. There was a pending requirement for a new intermediate caliber. If we could improve the consistency of the terminal effects of our current 5.56mm round and use it as a temporary solution, it would bridge the gap until we could get the requirement going for an intermediate caliber. The intermediate caliber requirement remains in the discussion phase. Instead, our development resulted in a round that equaled the performance of the current 6.8mm round. Remember the Belgian SS-109 ammunition? It was selected as the NATO standard in the U.S., and was designated the M855? Well, that ammunition outperformed the Vietnam era M193. In a similar way, our improvements have now given us a 5.56mm round that gives us the performance of the current 6.8mm round. Of course, with the same technology approach, we know today that we can get a better performing 6.8mm round and 7.62mm round than the NATO standard 7.62x51mm M80 Ball.

When we put our solicitation out on the street, we didn’t know about the Army activity to improve the M855 round nor did we know that SOCOM was developing an improved round through the Navy’s ammunition development group at Crane, Indiana. The Navy liked the wording in our solicitation and asked if the USMC wanted to join forces with them in developing a new round. We formed a joint Navy/SOCOM/USMC team and used the USMC wording to establish the requirements for the new round.

Tell us what makes this round different from what is being used now.

It basically comes down to the design of the projectile. Look on line and you can see the cross section. It’s an open tip match determined by DOD and military services lawyers to be consistent with U.S. law of war obligations. By using this type projectile, we gained the flexibility to select the design of the overall projectile configuration. The design work was done by Federal Cartridge Company. They came up with a combination of a reverse draw projectile with a lead core that is crimped down into an open tip match.

With Federal building the round, now you have to check compatibility with both the M4 and the M16A4.

USMC requirement was that it had to work in the M16A4 because, at that time, that is the rifle that all USMC infantry was using. M4’s were only for special applications, officers, etc. The new round was initially designed to work in a short barreled rifle so we had to confirm that it would work in the longer-barreled M16A4. We’ve gone through three iterations of testing that have used a total of 30 guns firing anywhere from 9,000 to 15,000 rounds per weapon. We tested for function, reliability, corrosion, accuracy, you name it.

What about environmental testing, like hot, cold, sand and dust?

Yes, it was full up testing in all environments.

How did you evaluate terminal effectiveness?

You know, you can’t do it well because it’s so hard to get volunteers (just kidding!) so we shoot into ordnance gelatin as adopted by government agencies. A few years back there was a joint wound ballistics Integrated Product Team (IPT). It had Army, Navy, USAF, Coast Guard and virtually every DoD organization – it was really joint, and that meant everybody. What they determined was that each agency used a different methodology for testing terminal effects, so they decided to write a charter, a test plan and gelatin block procedures. Those procedures even included how the gelatin was made, verified, and validated. With a standard gelatin block that everybody could use, terminal effects could be studied and data could be shared. Next, the IPT established criteria for how the projectile should perform in gelatin. We compared our results to the specification and also compared it to M855. Again, you can’t confirm this is what it will do in the human body, but it’s the best we can come up with. Buford can give you all the details, but essentially his eight points are:

Is Blind to Impact Yaw

Limits penetration – 12-18”

Resists yaw in tissue – no earlier than 12” is desired

Continues on shot line after penetrating tissue

Is barrier blind

Limits fragmentation

Performs consistently from 0 – 300 meters

Is accurate enough to engage human targets to 600 meters

Sal, this all sounds too easy. Surely you came up against some problems along the way.

Oh, sure there were problems. Field trials showed that the Mk318 Mod 0 did not exactly match the ballistics with the reticle pattern of the sight being used. The original ammunition’s exterior ballistics differed from the sight’s reticle pattern because it was originally designed for a 14.5-inch barrel. Since the Marine Corps’ primary service rifle is the M16A4 with a 20-inch barrel, we went back to Federal to adjust the ballistic coefficient. About this time the issue about environmentally friendly green ammo came up and we had to take a look to see if it was possible to replace the lead and still meet the specification. We found that we could replace the lead with copper, stretching the jacket around ever so slightly so it allowed us to crimp the nose even more. With that, the ballistic coefficient went up allowing the round to fly more efficiently through air with a better trajectory. Now it’s a ballistic match to the stock off-the-shelf reticle patterns that the Marine Corps uses, like the Trijicon ACOG sights. We named the improved round the Mk318 Mod1.

So, how do you avoid confusion with the new round to others that are already fielded?

There are two different configurations. The original round was adopted as Mk318 Mod 0. This is a copper jacketed, open tip match, 62 grain projectile. If you don’t know ammunition well enough you might confuse it with the Mk262 which is a 77 grain projectile. The Mk262 is an open tipped match round used by the Special Ops community. Since we were worried about confusion with the Mk262, we had to take another look at the color of the tip. Every color was taken except for solid silver so we decided to nickel plate the entire projectile. As we now jokingly say, “All Marines will have silver bullets.” That round hasn’t been fielded yet, and a potential production contract is in the future. I can just see the Marines out there polishing bullets.

Who will produce the new ammunition?

The government owns the drawings in the Technical Data Package (TDP) so Crane will procure it through open competition. There are a lot of top-notch ammo manufacturers out there.

What about the legal wickets that had to be passed? Years ago, we used to pass any new ammunition by the legal department at the Pentagon. Hays Parks was in charge in those days, but I’ve learned he’s retired.

When I first was given this project, I spent many hours talking about the legal aspects of a new round with Supervisory Special Agent Buford Boone (ret.) at the FBI, BRF and others, including Hays Parks. Hays retired about a year ago and is currently working under a support contractor for another Government agency. Fortunately, we still have access to him. I needed his input for all of our written documents. Anything put into writing that becomes public information is subject to intense scrutiny. The International Committee of the Red Cross (ICRC) watches the development of every new round very carefully and is quick to point out what they perceive as any violation of the “Law of War” declarations. Even though other ammunition very similar to this has passed the legal review, we could not afford any misinterpretation. We don’t want to give any reason for the ICRC to file a complaint that would delay the fielding. Hays has a lot of experience as the U.S. negotiator on proposed law of war treaties related to military small arms ammunition. I requested his assistance in developing a round that would meet the capabilities we needed and be consistent with our law of war obligations. For the data Hays needed, the FBI served as the independent laboratory.

What about compatibility with other service rifles in NATO?

The testing we did was M16A4, M4, M4A1, M27 and we also tested it in the SCAR. We have not tested other country’s guns, but there are some that are currently evaluating it. It’s public knowledge that Canada has adopted it.

Is there a tracer version?

No, there is no tracer planned for this round.

So that means it’s strictly as a rifle cartridge.

On our last test, we took 16,000 rounds, linked it, and successfully fired it through the M249 to confirm compatibility for emergency use; but yes, the round is strictly meant for our rifles.

What about accuracy of the round?

The performance is phenomenal. The way the specification is written, we focus on dispersion, not accuracy. The reason is that we define accuracy as a combination of the gun, the optic, and the shooter. Whereas, the dispersion of the ammunition is set at 2 Minutes Of Angle (MOA) at 100 meters.

If you ever get a chance to read the spec, the Mk318 MOD 0, it shows the MOA no greater than 2 at 100 meters. If you read the spec of the M855, the average standard deviation is not to be more than 2MOA. There is a big difference. We’ve proven that you can have a very large group and still meet the specification.

When you were managing this program you faced a lot of challenges. What was the biggest?

In order to get buy-in from Marine Corps senior leadership, I had to prove to them that this was a technically superior round of ammunition. I had to present the results of extensive testing.

What is next? You just now going to field this round, is the USMC working on another round?

Well, I’m still putting this one to bed. There is some additional testing that needs to be done. The USMC has type classified, adopted, and issued the Mk318 Mod 0 as an interim solution until formal testing has been completed on the Army’s M855A1. The decision on which round (Mk 318 Mod 1 or M855A1) will be fielded will be made within a year.

We’ve been working on improved sniper grade ammunition. A joint Navy, SOCOM, USMC requirement yielded the AB 39, 7.62mm round. The projectile is the same as the AA11 but it uses a different primer, propellant, and amount of propellant. Now we have an off-the-shelf round that gives consistent performance lot-to-lot, shot-to-shot. Lower dispersion is achieved through 1,000 meters.

Now we are looking at the barrel geometry. A twist of 1:12 is not ideal for this projectile so we developed computer models and simulated firing with faster twist rates. We’ve had test barrels built for us, and just finished firing them using ballistic radar. ArrowTech, who developed PRODAS simulation software, has been tasked to determine the optimum twist for the barrel configuration based on this radar data. Eventually, the USMC may be going to a different twist rate that may include changes to land and groove configuration.

Finally, the Army is looking at improving the machine gun ammo and we’re just keeping track of what they’re doing.

Thank you, Sal for taking the time to provide this excellent information for our readers. We truly appreciate it.

You’re more than welcome. It has been my pleasure.