In the early 1980s a requirement came down from the U.S. Army for a new pistol that would replace the legendary but well aged M1911 pistol. With the new NATO standardization, the new pistol would be chambered in the 9x19mm NATO cartridge: hence the beginning of the XM9 program. This would be entered by several manufacturers including Smith & Wesson, Colt, FN, H&K, Star, Beretta and SIG Sauer. After the testing was done and the reports were in, there were only two left standing: the Beretta 92F and the SIG Sauer P226.

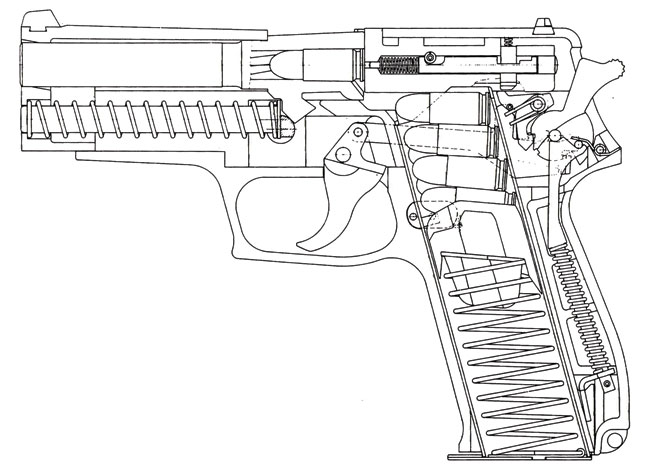

SIG Sauer had been in the pistol game for many years. For their entry in the XM9 program they would design a new pistol to enter. Based on the P225 and P220, the new pistol would be chambered in 9x19mm and have a magazine capacity of 15 rounds. This was to be a full size duty combat pistol. Designated the P226, the pistol had a 4.4 inch barrel and weighs about 34 oz. On the original pistol, the slide was manufactured from a heavy gauge, mill finished sheet metal stamping with a welded on nose section that had an internal barrel bushing. The breech block was a machined insert attached to the slide by brazing and a heavy roll pin. The breech block was not heat treated and the pin was prone to breakage. In 1996, the manufacturing of the slide was completely redone. It was from then on manufactured from a single piece of stainless steel. This eliminated the shortcomings of the original design and made the pistol that much better than it already was. The P226 slide incorporates an internal firing pin block that is not disengaged until the trigger is pulled all the way to the rear making this pistol perfectly safe to carry loaded with a round in the chamber. Unlike the M1911/M1911A1, which would discharge if dropped on the muzzle from 5 feet, the P226 could be thrown against a wall and it would not discharge.

The frame of the P226 is manufactured from aluminum and has no manual safety. It has a double/single action mechanism. The first shot has a long and heavy approximately 10 pound trigger pull and after that the pistol has a lighter approximately 4.4 pound trigger pull. There is a decocking lever on the left side of the pistol that allows the pistol to be safely decocked.

When the final votes were in, the winner of the XM9 trial and the next U.S. service pistol would be the Beretta 92F. Since that day, no two pistols would ever have such competition than the Beretta 92FS and the SIG P226 pistols. Performance was equal, spare parts and magazines from SIG brought the cost over that of the Beretta, hence the Beretta won. Which is the better pistol, the Beretta or the SIG? Well, that is up to the individual. The Beretta has been in service as the main pistol for U.S. forces for nearly 30 years but the P226 would find its niche within the military as well.

Later in 1988, another requirement came out from the U.S. Army for a more compact pistol to be carried by CID, MP, Navy and other special groups. The pistol chosen for this would be the SIG P228, a more compact version of the P226. The P228 has a shorter 3.9-inch barrel and weighs 1.82 pounds. The pistol has a 13 round magazine capacity and would be type classified as the M11 pistol. It was required to have a phosphate finished barrel and controls. This pistol is identified by the markings on the right side of the frame. On the left side of the disassembly lever states “US” and on the right states “M11.”

In the late 1980s, American law enforcement went through a transition as well. The day of the wheel gun was coming to an end and police would be arming up with semiautomatic pistols. It is always a natural choice for many police agencies to adopt weapons either used by the military or tested by the military as many police agencies do not have personnel with the expertise to run a weapons replacement program. The Beretta pistol became one of the most popular weapons in law enforcement in the country. However, SIG got its share of that market as well. The P226 became another common weapon seen on a policeman’s side. The trigger was identical to what they were already used to with the double/single action. The officer nearly tripled his load in the gun going from 6 to 16 rounds. The main training issue was getting them to use the decocking lever over the traditional way they did for years. SIG might as well have been able to have a larger portion of the market but they at the time were perhaps the most expensive pistol in the market being used by law enforcement. Many police agencies tested and liked the pistols but they were just cost prohibitive. The SIG line did very well in the federal law enforcement market getting adopted by agencies such as ATF, Secret Service and customs to name a few. With the introduction of the .40 caliber and the P229, this assisted SIG greatly with law enforcement sales including more recently with the U.S. Coast Guard once they fell under Homeland Security.

Early in the transition, Navy SEALS got Beretta pistols and began using them. The pistol experienced some catastrophic failures where the slide would break and exit off the rear of the pistol hitting the shooter in the face. Although nobody was ever seriously injured, an investigation took place to find what caused this issue. What was found after the investigation was that the pistol was in fact fine; the problem was the first runs of M882 Ball ammunition were loaded to near proof pressures. This same ammunition that broke slides on the Beretta cracked frames on the SIGs. Despite the findings, the SEALS chose to go with the SIG P226 as their main sidearm; probably in the late 1980s. This was the beginning.

Looking at the time frame of the onset of the XM9 program, this was basically peace time. The SEALS had fairly little combat experience from the end of the Vietnam War until the onset of Gulf War 1. In the calm of peace, the operators got used to the light weight and light recoil of the 9x19mm pistol. They were very fast and accurate with their P226 pistols. Once they went into combat during Gulf War 1, they saw the drawbacks of the 9x19mm cartridge. In the early 1990s when SOCOM was created and all special operations forces fell under one umbrella, one of the first procurements was an OHWS or an Offensive Handgun Weapon System. This was chambered in the classic .45 Auto caliber. The pistol that won was the H&K MK23. This is a very large handgun, but it needs to be kept in mind this was an offensive or primary weapon comprised of a pistol, sound suppressor and laser aiming module. It was heavy weighing in at 3.2 pounds loaded with 13 rounds of .45 caliber ball ammo compared to 2.1 pounds for the P226. The Mk 23 was significantly larger. With the MK23 being so much larger and heavier, they tended to sit in the armories and the operators would go back to their SIG pistols.

In the late 1990s, SIG produced the first Navy specific P226, the MK24. This differed from the standard P226 in that it had the new stainless steel (blackened) slide and the new SIG rail on the front of the frame. This was a proprietary SIG rail, not the standard Mil-Std 1913 rail. The pistol had a U.S. Mil-Spec chrome lined bore and chamber and was identified by an anchor on the left side of the frame. This pistol served with distinction throughout both Gulf Wars and any other operation the SEALS were involved that never happened.

In 2011, the SEALS got a new pistol, the MK25. This was a further modified MK24 with the major change being to the front rail that now changed to the Mil-Std 1913 rail configuration. Also added to the pistol are tritium night sights. The pistol frames were first made in Germany and are identified by the “DE” on the right side of the frame above the trigger. The frame will also state “Frame made in Germany-Sauer.” Both the MK24 and MK25 pistols have the U.S. mandated UID sticker, which is a barcode that contains the serial number, cage code and model of the firearm. Originally, the stickers were placed on the right side of the slide. This way you could verify easily the serial number of the firearm’s frame with the UID sticker on the slide. Later, SIG was required to place them on the left side of the frame. UID or Unique IDentifcation labels are on all U.S. small arms. Like the MK24, the MK25 has a chrome plated bore and chamber.

This author attended the 2012 Warrior Challenge at the King Abdulla Special Operations Training Center (KASOTC) in Amman, Jordan. Special Forces teams from all over the world competed for the gold. Many of the units were unable to bring their own weapons for many different reasons and weapons were provided to them by the training center. There were two different pistols offered, the Glock 17 and the SIG P226. The units had their choice. The environmental conditions at the training center are exactly what you would expect of that region of the world: talcum powder-like dust and it gets everywhere. This is trying on any weapon system; anything mechanical with moving parts for that matter. These operators had very grueling competitions. When the weapons would come back at the end of the day they were full of sand. I had the opportunity to inspect and help clean up some of these weapons. The SIG P226 pistols experienced no malfunction from the information received. When these pistols were disassembled to be cleaned, well there were no words: the insides were covered in sand. Some of the pistols we had to hammer the slides open. Most pistols or any weapon would not be functional under these conditions. The SIG P226 performed excellently. By the way, the pistols that had to be hammered open were on the operator’s hip as they low crawled in the sand to an objective. They were not fired after that. KASOTC procures the best weapons available and money is not an object. This was an excellent testament to SIG quality.

Everyone wants the same weapons as the military has, and especially the same ones as Special Forces have. SIG had seen the market for the MK25 pistol in the commercial sector and approached the Navy to ask if they could sell the same pistol to the commercial market as they do to them. They were granted that permission. According to SIG, there is no difference at all between the pistols sold to the SEALS and the MK25 they sell on the commercial market.

The test & evaluation pistol was pristine as one would expect from SIG. The finish was immaculate and no machining marks were anywhere to be seen. The pistol was provided with three magazines and a trigger lock. The ammunition used was provided by Pierce Ammunition in Buffalo, New York. This is a fairly new company but manufactures high quality rifle and pistol ammunition. The ammunition used was the Pierce 9x19mm 124 grain full metal jacket. During testing, 500 rounds were fired. The pistol was not cleaned during testing. Prior to it being fired it was cleaned and lubricated with G96 synthetic CLP. There were no failures of any sort. Accuracy was excellent; the pistol shot way better than this author. Group sizes averaged less than one inch at 15 yards.

The MK25 is certainly a treat for the commercial market. It is not often; nearly never, can a civilian obtain the exact weapon that is provided to the U.S. military. You can get similar models but there is always something different like the font of the marking, additional id codes, different serial number range and so forth. The MK25 is the real deal. Collectors and shooters alike have been buying these pistols up as fast as SIG can make them.