By Dan Shea

“On accessible terrain he who occupies the High Ground and ensures lines of supplies will fight to advantage” -Master Sun Tzu

High Ground Defense is a relatively new name to the defense and small arms industry, but not the people involved. The HGD engineers have many decades of experience with small arms, and in specific, successful M134 series designs and manufacturing. They have spent the last several years preparing a pallet of solutions in small arms.

Aside from the M134HGD Gatling Gun system, HGD offers some very innovative, lightweight, belt-fed machine guns that include evolved variants of the M249/Minimi in 5.56x45mm, 7.62x51mm, and 6.5 Creedmoor. Their company offers other services:

- Weapon System Design

- Land/Sea/Air Mounting Solutions

- Electrical/Avionics System Design/Integration

- Rapid Prototyping

The M134 “Minigun” series of Gatling guns are electrically driven, mechanically operated automatic machine guns. The distinction in description is important. If there is a belt of ammunition and the barrel cluster is rotated, the ammunition will cycle through the mechanism and fire when presented to full lock up to the barrel. This can be a very dangerous situation around persons unfamiliar with this cycle of operation.

The M134 was a downsizing of the M61 20mm Vulcan six-barreled automatic cannon that was made in 7.62x51mm for use on rotary- and fixed-wing aircraft during the Vietnam War. General Electric (Yes, the “GE Brings Good Things to Life” General Electric) was the design and build contractor. GE in Vermont designed and built many weapon systems in that time period in its skunk works in Burlington. See our interview with Bob Chiabrandy, designer of the M134 among others, “The Man Who Designed the World’s Fastest Gun” on smallarmsreview.com. The interview was done by George Kontis, small arms engineer extraordinaire, who worked with Bob at GE before George became FNMI’s chief engineer.

The M134 has gone through a number of upgrades by different manufactures, each trying to deal with some of the idiosyncrasies of the system. HGD’s engineering staff have many decades of experience in this area, and prospective end users should discuss the new delinker-feeder systems, variable rate of fire FCU, lightweight battery packages, caliber changes, and many other seriously functional upgrades.

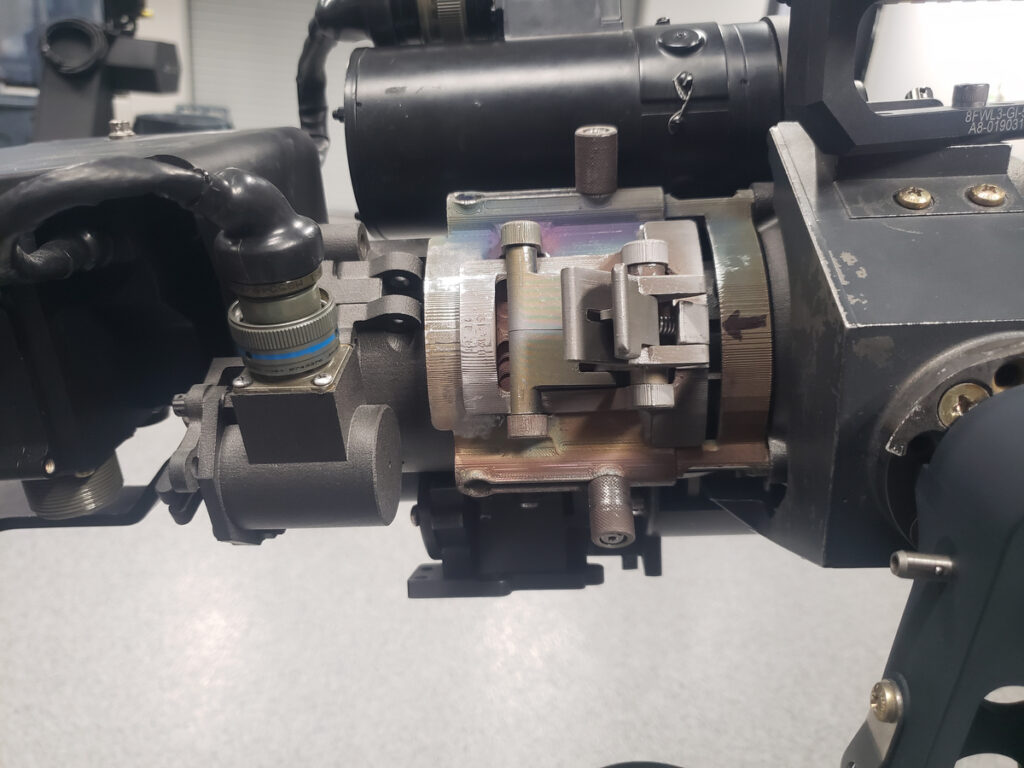

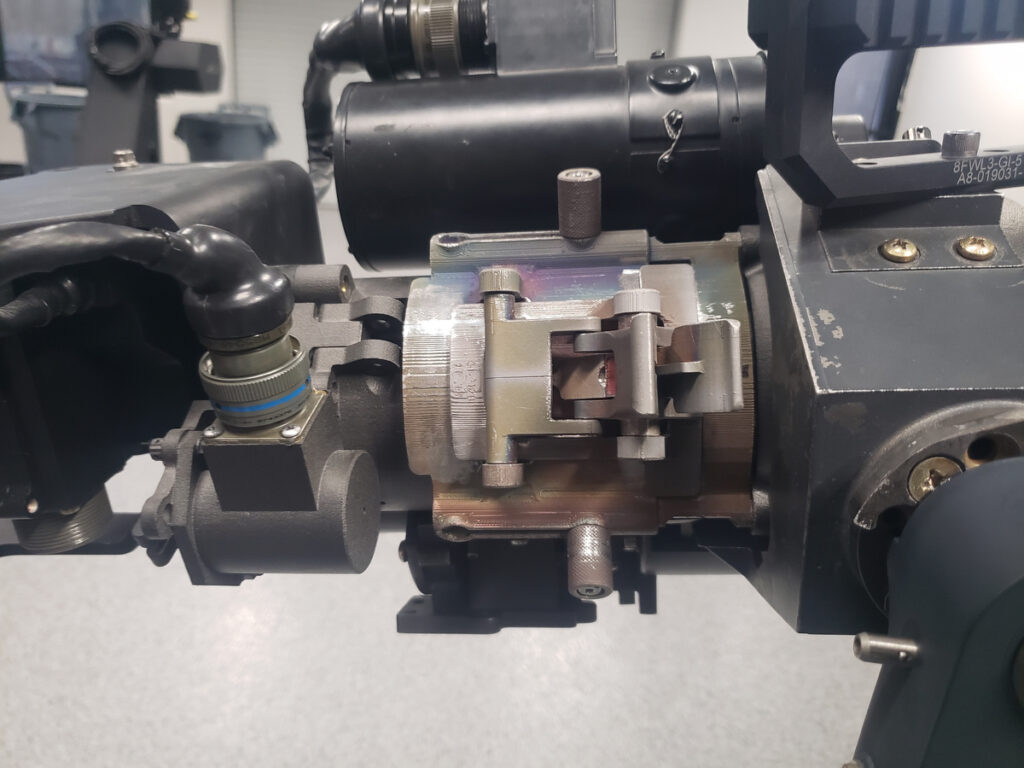

High Ground Defense’s delinker-feeder loading system (above) is unique and truly easy to use. Sliding the ammunition belt into the delinker-feeder is generally a three-handed job even with some of the newer open-door types. The HGD system allows the belt to quickly be held in position to start feeding, with one hand locking in place, then the doors can be closed. Clearing a link jam is also much easier with the amount of access provided.

HGD’s feed cover (above) replaces the old assembly and safeing sector. The safeing sector’s job is to complete the elliptical path the bolts are traveling in, and when opened, interrupt that path, and keep the bolts from going into battery with a live round. Remember, this is a mechanically operated gun. If the bolt goes into battery on a live round, it will fire. Period. This is where many accidents and several deaths have occurred. The safeing sector must be opened before working on the gun, and it takes several minutes to do. With the HGD cover, the path is interrupted with one hand motion. Once the levers have been activated, no bolt can go into battery.

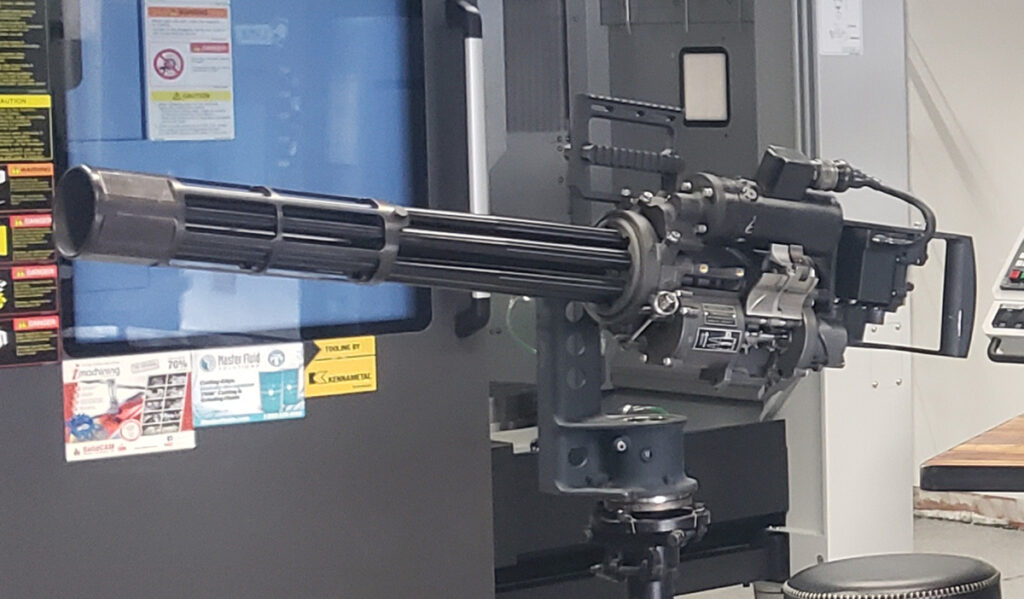

One of the newest designs that High Ground Defense is presenting is the ADVANTAGE 7.62x51mm Gatling Gun (above). It is a three barreled design, and very lightweight. The basic M134 gun weighs 85 pounds (39kg) and there have been some lighter models, however, there were issues. HGD’s ADVANTAGE is nearly half the weight, it weighs 46.45 pounds (21kg). A key feature is the mechanical barrel cluster rotational lock for absolute safety when the system is in the SAFE condition. It has similar barrel spacing, bolt assemblies, and bolt cam path as on existing M134 platforms, but uses an alternative ammunition feeding, delinking, and transfer mechanism. The drive system uses a brushless DC servo motor with closed-loop positional feedback for precise control of all rotating components. The gun has a longitudinal bolt searing safety mechanism, self-contained hardware barrel clamp with a threaded adapter for various muzzle devices. It has integrated suspension lug mounting provisions, as well as multiple feed inlet locations for optimal feed chute orientation. It’s 41.2 inches long (1046mm) and 8.5 x 7.7 inches in diameter (215mm x 195mm).

High Ground Defense’s machine shop (above) features the DN Solutions (Doosan) DVF 4000 vertical 5-axis machining center (CNC). It has a 40-tool automatic tool changer which expands to 120 tools, allowing HGD to work with complex prototype designs and production. The DVF 4000 was chosen for its versatility. With linear scales on X, Y, and Z axis and rotary scales on the B and C axis, they can program extremely accurate positioning and repeatability. Manufacturing Engineer Jay Goodrich is intimately familiar with DN (Doosan) systems, having been involved in specifying, selling, and installing CNC machines in the past. The Lynx 2100LSY horizontal lathe is another DN Solutions offering. A highly accurate CNC turning machine, it has wider support structures for the X and Z axis, as well as the tailstock traverse. It’s very stable, allowing for very accurate prototyping and production of parts. Like many modern manufacturers, HGD is heavy on engineering and quality prototyping with these capabilities, while sub-contracting some parts and operations to trusted vendors.

The HGD 249 is standard size, (above) and the HGD 249CQB (not shown, but we were enamored of it) has an ultra compact receiver. Born from the M249 Para-style machine guns, the CQB system in 5.56x45mm has an overall length of 32 inches (813mm), a barrel length of 9.75 inches (248mm), and a weight of under 14 pounds (less than 6.35kg). The shortened steel receiver has an ArmorLube finish and a hard chrome-lined quick-change barrel. There is an optional folding stock. The rate of fire is around 800rpm. With the short barrel, the effective range is claimed as 800m. The 249 variants can be ordered without the magazine well capability.

The HGD 7.62mm SAW is a belt-fed 7.62x51mm NATO light machine gun. There is no magazine feed, just the M13 disintegrating links. HGD also offers this in 6.5 Creedmoor as well as with suppressors. The steel receiver has an ArmorLube finish and the quick-change barrel is hard chrome-lined. It uses a mono-block gas system.