ABOVE: The M240B here is equipped with the Trijicon Machine Gun Reflex Sight ballistically calibrated for use on the M240 and .50 Cal. M2.

Three almost equal in weight and punch

There is no faster and more delay-free fire support for dismounted fighting forces than from the machine gun man’s 7.62mm machine gun’s sustained fire. The correspondingly long range and effect in the target are the determining factors here.

Battle Proven and Reliable but Heavy to Carry

The M240 Machine Gun is the principal suppressive fire weapon for the infantry platoon and company. M240 series is used in the U.S. Army as the M240B, USMC and USN as the M240G, and as either “B” or “D” for USAF services. The M240B is one of the most essential and widely used small arms in Iraq and Afghanistan. The M240B’s weight unloaded is 27.1 pounds (12.3kg). Any soldier who has ever served as a squad automatic weapon gunner is resigned to the burden of lugging a heavy weapon and ammunition on patrol. The M240B offers absolute reliability, long range and exceptional service life, but its coaxial origins limit its ergonomics in dismounted role, length and weight.

Newer Concepts

Textron Systems, for example, has developed both weapons and cartridges to reduce soldier load by about 40 percent with machine guns in both 5.56mm and 7.62mm caliber with use of cased telescope cartridge in polymer casings. USSOCOM, in conjunction with the USMC, was in 2017 seeking sources within the national technology and industrial base with the ability to provide 5,000 units .338 NM belt-fed medium machine guns: a complete machine gun system to include weapon, suppressed barrel, tripod and any tools needed to conduct basic maintenance. The lightweight medium machine gun (LWMMG) should fire the belted .338NM round of ammunition with a polymer case. The LWMMG should weigh less than 24 pounds unloaded with a barrel length of 24 inches (Source: Federal Business Opportunities, May 11, 2017). The .338NM ammunition is heavy to carry, and that’s not what the squad’s automatic weapon gunner wants to carry on tactical movements. The .338NM chambered LWMMG would need a two-man MG-team.

Contemporary Machine Guns

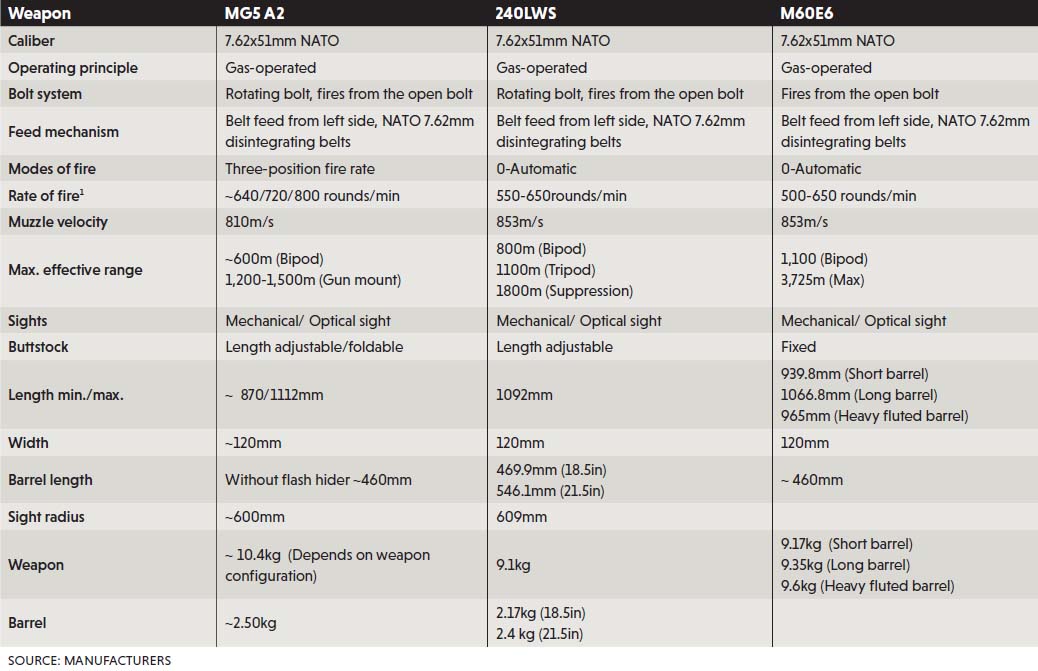

The purpose of this article is to describe the three machine guns: MG5, 240LWS and M60E6.

MG5

The operations of the Bundeswehr (“Armed forces of Germany”), especially the mission in Afghanistan, had shown that there was an urgent need for the 7.62mm caliber class of medium machine guns. Bundeswehr’s MG3 machine gun is no longer able to meet the requirements of a modern machine gun, and it requires a lot of effort to keep it in use. Rheinmetall’s MG3 will therefore be replaced by a new machine gun. As part of the project “New Machine Guns,” the successor of the MG3 had to pass several test series.

The MG5 from defense manufacturing company Heckler & Koch (HK), the most prolific German weapons maker, was chosen as the successor to the MG3. The MG5 (formerly known as the HK121) is a general-purpose machine gun. The MG5 is gas-operated and chambered for the 7.62x51mm NATO round with M13 disintegrating metallic links. MG5 offers an intelligent and contemporary build standard, with numerous technical and ergonomic innovations with features like belt feed with loading indicator, cocking in all safety positions, and, with an adapter, it can be installed on all mounts and tripods originally developed for MG3 machine guns. The MG5 can be reconfigured to a mounted, universal, Special Forces or infantry machine gun, without special tools. It has a special buffer that reduces recoil forces and stabilizes the rate of fire and has an adjustable rate of fire (3-positions). When HK designed the MG5, special emphasis was placed on robustness, reliability, ergonomics and easy handling. The MG5 withstood barrel obstruction testing to NATO-AC225/D14 standards (soft core and steel core ammunition DM111A1, DM151). The result is a compact, medium machine gun, which is well-suited for dismounted infantry both by the weapon’s design and its fire superiority in combat.

Turning away from the system of MG3’s short, recoil-operated loading mechanism to the indirect gas pressure loader was a significant improvement in the shooting behavior of the weapon and improved hit results were achieved. With the MG5 it’s now possible to fire against targets from a standing firing position, an option that was impossible with the MG3. In the prone position, especially when using the riflescope, it’s possible to achieve accurate hit performance, which was previously possible only with the help of a tripod. For a medium machine gun, this is a very considerable precision.

The weapon’s operation is almost similar to that of the MG4 light machine gun. The safety and three-position fire rate selector levers are ambidextrous, the butt stock can be folded depending on the variant, and numerous Picatinny rails allow installation of optical sights and other accessory options for aiming aids such as optics/optronics, laser/light modules or clip-on thermal scopes. The quick-change barrel has a heat shield and a carrying/barrel exchange handle. A hot barrel can be replaced without protective gloves. The iron sights consist of a collapsible front sight and a height and windage adjustable rear diopter sight. The charging handle is on the right side of the weapon. For feeding, 50-round belted ammunition pouches or 120-round belted ammunition boxes can be mounted on the left side. The MG5 can be installed on all mounts and tripods originally developed for MG3 machine guns, using additional adapters.

The MG5 is available in several configurations: a standard version, a shortened and lighter infantry version (MG5 A2 with a fixed, foldable and length adjustable buttstock) and a version for installation in weapon stations. The Standard and Infantry versions which are intended for dismounted infantry feature a quadruple magnification riflescope and integrated red dot in addition to the mechanical sighting (front/rear sight), allowing for intuitive and fast targeting at short distances. The MG5 is compatible with the equipment of the German “Future Infantry Soldier-Enhanced System” and is set to become the Bundeswehr’s standard issue machine gun. The defense ministry has ordered 12,733 units, with a price tag of some 200 million euros ($222 million). 200 units had been delivered in January 2018. The rest will be delivered in coming years.

240LW and 240LWS

The combat-proven M240B machine gun has been noted for its reliability, but its weight (12.5kg) has not gone unnoticed. The infantry men want a modern machine gun that is lighter to carry and handy to operate. M240 is the U.S. military designation for the FN MAG.

Barrett Firearms, the manufacturer of firearms and ammunition, including the famous M82A1 which has been purchased by over 40 military organizations worldwide, took the initiative to make the M240B lighter and designed the 240LW taking advantage of cutting-edge modern manufacturing techniques. Barrett brought their lightweight M240LW prototype to the SHOT Show, Las Vegas in 2011. Unlike the M240L, which is in service in the Army, Barrett does not use any expensive materials like a titanium receiver and polymer trigger frame or manufacturing techniques to decrease weight. Barrett instead decreased weight by trimming off as much metal as feasible and decreased manufacturing costs by making the receiver in two pieces and then welding it together. They managed to trim about 6.2 pounds off the standard M240B. Due to some changes that Barrett has done to the existing 240 components, the life of the receiver and internal components are prolonged about 20,000 rounds longer than the standard and current FN variants. Cosmetically they will look identical, but there are some dimensional differences. In June 2014 the gun went through a process of intensive testing. Barrett took a step further with the new 240LWS. Small Arms Defense Journal, Volume 8 Number 5, November 11, 2016 (www.sadefensejournal.com/wp/?p=3758) contains a comprehensive article about Barrett 240LWS.

Compared to the 240LW, the 240LWS’ buttstock is shortened, the controls are moved forward, and it’s lighter and more maneuverable.

The 240LWS gas-operated, open-bolt, air-cooled and fully automatic machine gun has the same punch as the 240LW. The receiver is machined from forgings. The top cover has a 7-inch (17.8cm) MIL-STD 1913 optical rail, and the cover’s design makes it remain in open position, even with optics mounted. The ammunition is on M13 links and retains features that facilitate single-operator loading. The 240LWS has a quick-change fluted barrel, and the carrying handle folds in both directions for use with optics. The rear and front sights are folding types. The gas system has a 3-position adjustment. The Barrett Lightweight Handguard with accessory rail mounting points is mounted on the receiver, not on the gas tube. The folding bipod is quickly detachable. The Barrett telescoping buttstock has an adjustable length of pull and hydraulic buffer. Available colors are Black and Flat Dark Earth. Compared to the M240B, the 240LWS is 3.2kg lighter, and it should be an alternative to the more costly exotic M240L.

The M240L Machine Gun model of the M240B is 3.75 pounds (1.7kg) lighter than the M240B. It features a folding bipod, quick-change barrel assembly with integral carrying handle and gas system, feed cover, bolt assembly (which allows closing of the cover regardless of bolt position), plastic butt stock, integral optical sight rail and forward rails. The M240L MMG lightweight features are a titanium receiver, redesigned barrel assembly with re-contoured outer dimensions, titanium carrying handle, lighter weight gas housing and pistol grip/trigger frame assembly composed of a metal/polymer hybrid.

The ability to withstand high heat without any difference in shape is different between steel and titanium. If we compare the heat and cold stability of titanium versus steel, titanium is more thermally stable than steel; steel may bear around 2,700° F, whereas titanium can bear 3,300° F. The difference is 600° F (315.6°C).

The M240L’s combination with steel barrel and titanium receiver can cause trouble when the barrel is fired very hot. A quick barrel change cannot be performed then because the barrel is expanded in volume and sticks to the receiver. It has to be cooled down before it can be changed.

M60E6

This version is heavily upgraded compared with the famous 7.62mm M60 machine gun first used by U.S. forces during the 1950s and gradually replaced the 1919A6. M60E6 represents the latest improvements to the M60 Series of machine guns. Its predecessor, the M60E4 was developed in the 1990s for U.S. Navy SEALs. However, this initial weapon had problems and reliability issues; the later version of M60E4 made by US Ordnance solved these issues as the MK43 Mod 0. The M60E6 incorporates a number of improvements over the M60E4 and is a more reliable weapon. Like the forerunners, the air-cooled machine gun is gas-operated and belt-fed with disintegrating M13 links. It fires from an open bolt and features a quick-change barrel. Its design is light and compact which provides increased mobility and allows for accurate off-hand (shouldered) direct fire support. The top cover is made of forged 7075 aluminum with MIL-STD 1913 optical rail for mounting of optics and clip-on thermal sight. The belt pull is improved by 30 percent that provides increased reliability in harsh, dirty environments. There is an extra lock in the feeding tray that keeps the linked cartridge firm and safe, so when loading, the belt will not fall out. A receiver-mounted ammunition hanger provides a stable and secure mounting point for an ammunition pouch and isolates the feed tray from accidental damage. The ergonomic pistol grip with an improved trigger can be used with gloves. It has a push-button or ambidextrous safety. A new “captured pin” latch securely holds the trigger assembly to the receiver (in the Vietnam War, the pin could slip, and the detachable pistol grip with the trigger and sear group was lost in the jungle ground). It is light weight. The one-hand operated and light weight bipod is mounted on the receiver. The forearm/pistol grip for improved control has three M1913 rails for mounting aiming lasers and accessories. The buttstock is ergonomic with a hinged shoulder rest. It has quick detaching sling mounting points.

The M60E6 version with reversible gas piston is improved to be simple and easy to maintain. The gas regulation is self-adjusting. The front sight is adjustable, also on the spare barrel, which was not possible in the earlier versions and allows zeroing of primary and spare barrels. The offset barrel handle provides a clear sight picture and eliminates the need for a heat mitten for barrel changes. The Stellite alloy of cobalt-chromium alloys gives the barrels sustained fire capability and extended life. The hard chrome and induction hardening of the op-rod tube facilitates easier cleaning and increases the service life of the receiver. M60E6 is available with a short or a heavy fluted barrel configuration for application flexibility. The controllable rate of fire allows for accurate firing in off-hand, kneeling and prone positions. Also the weight is better distributed. Its relatively light weight and short length make it accurate when firing from the shoulder. All major components are directly interchangeable with other M60 configurations. M60E6 can be mounted directly or adapted to all standard NATO tripods and vehicle mounts.

M60E6 for the Danish Army

The M60E6 competed for the Danish Army’s machine gun replacement program against the MG5. In 2014 the M60E6 was selected as a winner and has been adopted by the Danish Army as the M/60. The M60E6 will replace the ageing M/62 (Rheinmetall MG3) machine gun, which has been used by the Danish Army since 1962.

The Danes’ M60E6 version differs a little to satisfy their demands, which includes several modifications like taking away the irons sights and using optic only, making it lighter, more accurate and easier to fire on the move. The complete weapons package includes optics, thermal sight, lasers, rangefinders and more.

The new MG will be used as a squad support weapon. The older LMG M/62 will remain in service with second-line units and as a vehicle-mounted machine gun, where weapon weight is not important. The selected M60E6 was planned to be phased into service at the end of 2014/2015, and the estimated cost of the program was $16.6 million for 700 M60E6s with accessories. U.S. Ordnance is the only company that makes the M60E6. It’s said that versions of the M60 are in service in many countries around the world. Among its customers are Mexico, Thailand, Philippines and Honduras.

Photos by Aud Håland