A bit of background: In the mid-2000s, during the war in Afghanistan, many soldiers were questioning the terminal ballistics – the stopping effect – the 5.56x45mm NATO round had at longer distances. A rifle’s purpose in war, of shooting an enemy soldier, is not so much to kill as it is to stop him from continuing what he’s doing. Make him cease to be a threat. Many coalition soldiers have stories about hitting the enemy center-of-mass at 600 meters only to have the enemy soldier fire an RPG or DShK in return, dying later, bleeding out 100 meters away. The projectile did not do the “stopping” part of the job.

In the mid-2000s, Karl Lewis of LMT Defense, and Greg Felton of Law Enforcement International Ltd (LEI) in the U.K., were involved in a program for another client. The requirement was for a reliable, maneuverable 7.62x51mm select-fire rifle. The rifle that LMT & LEI evolved was nothing short of amazing. Concurrently, the British MOD came out with a requirement for a designated marksman rifle in 7.62×51, semi-auto only. The basics were there, Lewis had to remove the full-auto feature and add a few needed design changes and they submitted what is now adopted as the L129A1 “Sharpshooter.” The weapon was an outstanding success, and after Afghanistan, the weapon system – initially purchased as a temporary measure – was adopted as a permanent system.

Which brings us to the L129A2: Sharpshooter II in 6.5 Creedmoor. Most readers of SADJ know that the military purchases “systems” as opposed to just shopping off the shelf and putting things together. It all must be tested together, then integrated. Thus, after the decade-long success of the L129A1 system, with lessons learned, the U.K. military called on LMT and LEI again to upgrade the system. The ammunition is changed, although the original 7.62x51mm NATO round from the L129A1 can be used in the L129A2 by switching out the barrel. The goal, with the 6.5 CM (6.5x48mm) round, is to extend the performance of the system another 200 meters and get some flatter trajectory. More on the ammunition later.

The Royal Marines have ordered an unspecified quantity in a dual-caliber configuration with the primary being 6.5 CM. As a DMR and as a sniper support weapon (SSW), this is an exceptional rifle, as shown in our range tests that follow.

Top: Original L129A1 rifle in 7.62x51mm. Bottom: New L129A2 rifle in 6.5mm Creedmoor.

The changes to the system are fundamental to the core rifle, and in the accessories used, which are all new to the Sharpshooter program. At the rear is the L129A1 as issued, with a Trijicon 6×48 optic. Eventually, the L129A1 was also upgraded to an SSW with the addition of a newer optic. To the front is the L129A2 as issued, with Leupold Mark 5 3.6-18×44 optic, TIER-ONE Cantilever Monomount, Atlas PSR-type bipod, and HUXWRX QD suppressor. L129A1 did not have a suppressor issued, but there were several trials, one of which Gemtech and LEI won to produce test suppressors. The new issue Sharpshooter II has the HUXWRX suppressor as part of the kit.

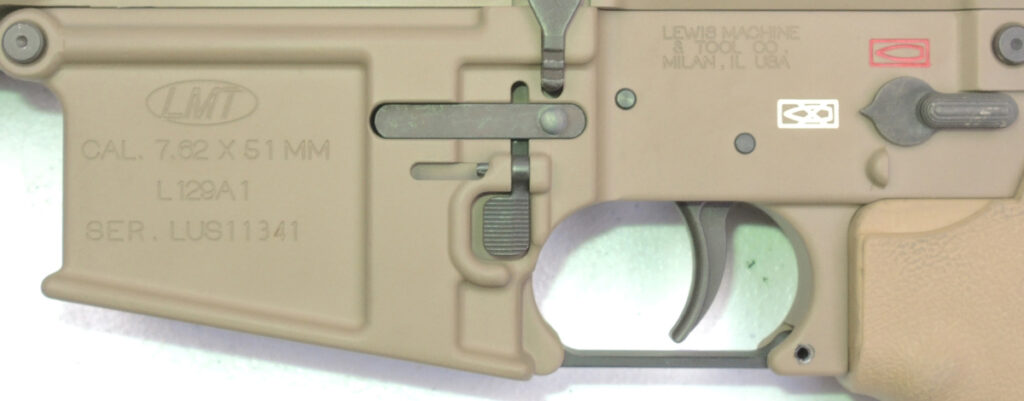

Markings of the L129A1 as 7.62x51mm and the L129A2 are “MULTI-CAL” because of the changeable calibers.

L129A1 front, L129A2 rear. The L129A1 featured the LMT SOPMOD buttstock, an excellent collapsible stock. The L129A2 has moved up to the fully adjustable .308 DMR buttstock, also from LMT.

L129A1 MWS Style lower, in front, L129A2 MARS-H style lower, at rear. Ambidextrous selector the same, A2 deflector, Picatinny rail top. Note the ambidextrous bolt hold open/release on the right side of L129A2. Inside, the L129A2 has the AXLE two-stage trigger. MWS is Modular Weapon System, MARS-H is Modular Ambidextrous Rifle System with an “H” to denote 7.62x51mm.

Left side L129A1 in front, L129A2 at rear. An ambidextrous magazine release is a feature of both rifle lowers.

Both rifles are direct gas impingement and have the signature LMT Monolithic Rail Platform design. Both change barrels in the same manner, with a split collet-type receiver and two properly torqued screws. The L129A2 (rear) uses the MLOK rail configuration as opposed to the Picatinny rail fore-end of the L129A1 (front). The L129A2 can accept the L129A1 7.62x51mm barrel if needed (but not vice versa). The new rail is extended significantly on the L129A2, and the barrel for the 6.5 CM is 18 inches with 1:8-inch RH twist, as opposed to the 16-inch 1:10-inch RH twist barrel on the L129A1.

L129A1 on top of L129A2, left side, showing the overall length difference. Both rifles have a full FDE color treatment with a durable Cerakote finish.

BIPOD

The L129A2 system uses the Atlas BT46-LW17PSR bipod, which is a very stable and popular bipod in the precision shooting community. It’s made from 6061-T6 aluminum with inner legs of 7075-T6 aluminum. The finish is a Type III Mil-spec hard anodize.

Leg positions are 0, 45, 90, 135, and 180 degrees, with the position/support components made of heat-treated stainless steel. This allowed us a variety of firing levels and supports. Very important to our test, the non-rotating legs added to the stability of the shooting platform, perhaps more than shooters might realize.

Regarding cant and pan, the Atlas bipod has a built-in, pre-loaded, tensionable 30-degree cant and the same 30-degrees of pan. This author is not a fan of panning on a bipod for a sniper system, but it has its place and is desired by many professionals. Cant, on the other hand, combined with the built in anti-cant bubble in the TIER-ONE cantilever mount, is an excellent feature for accuracy.

This is a very well-made bipod, with a footprint of 8 to 11 inches, getting low at 5.2 inches and up to a height of 9.6 inches. Almost every detail is well thought out. Even the springs and fasteners are made of stainless steel.

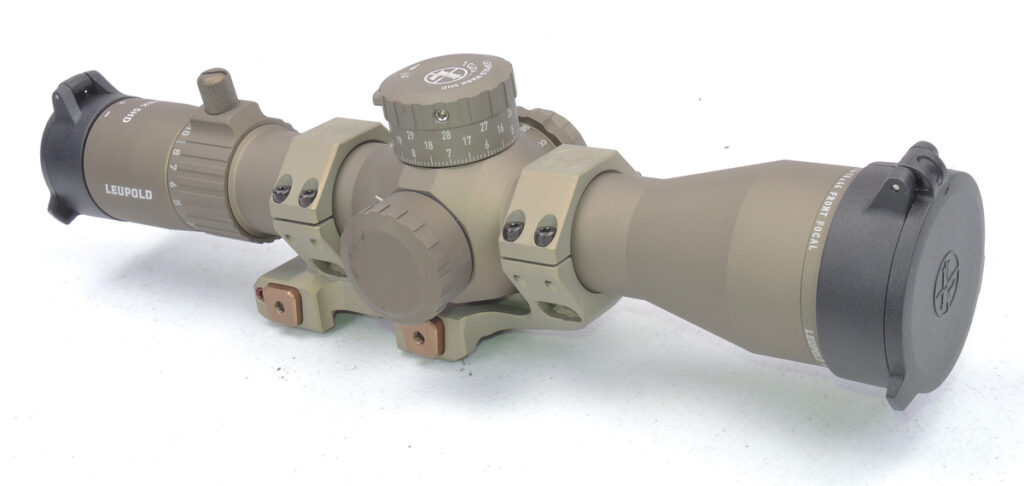

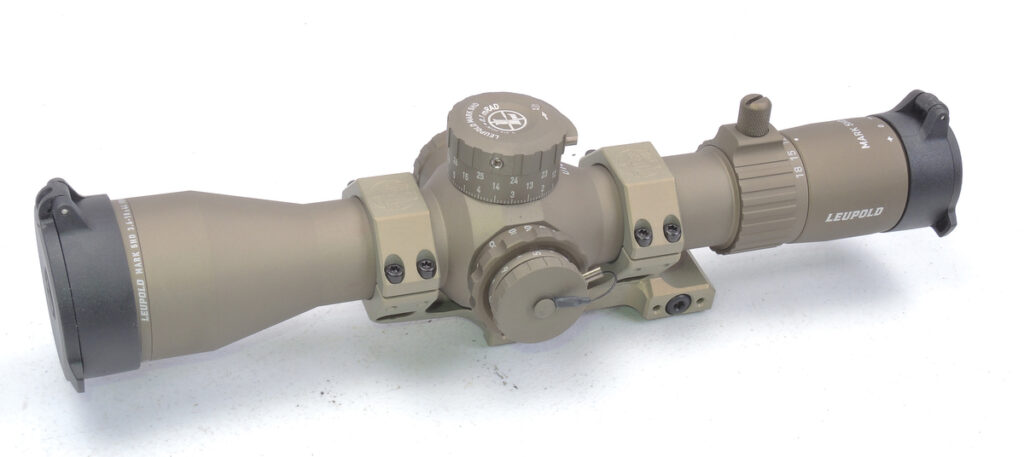

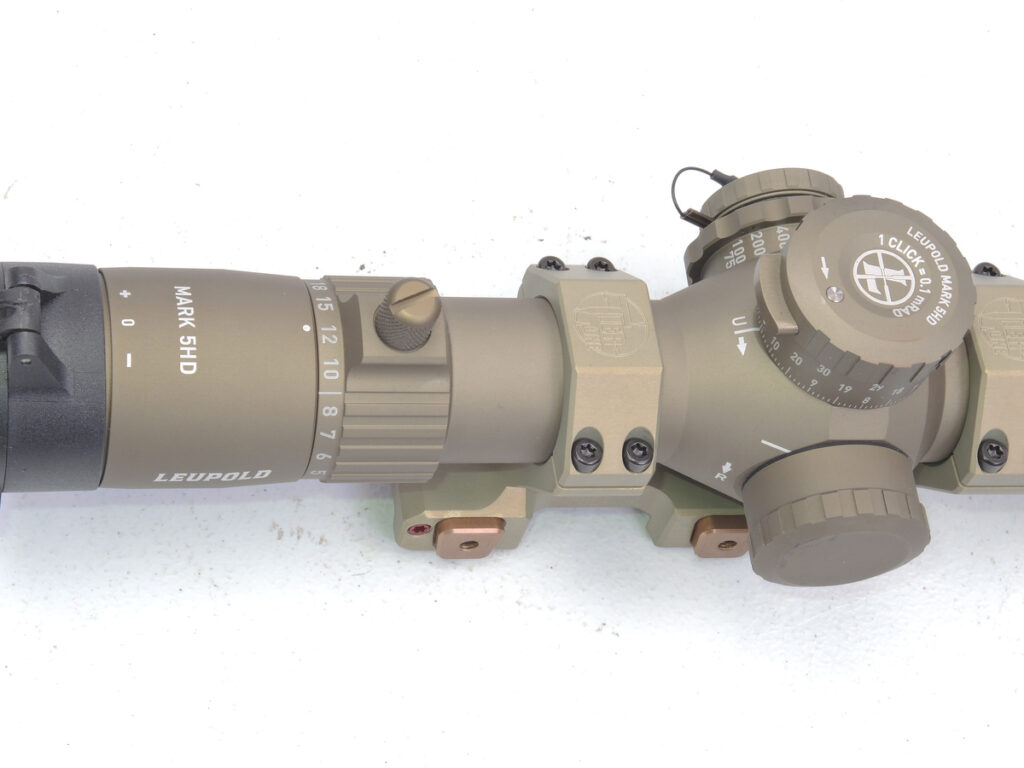

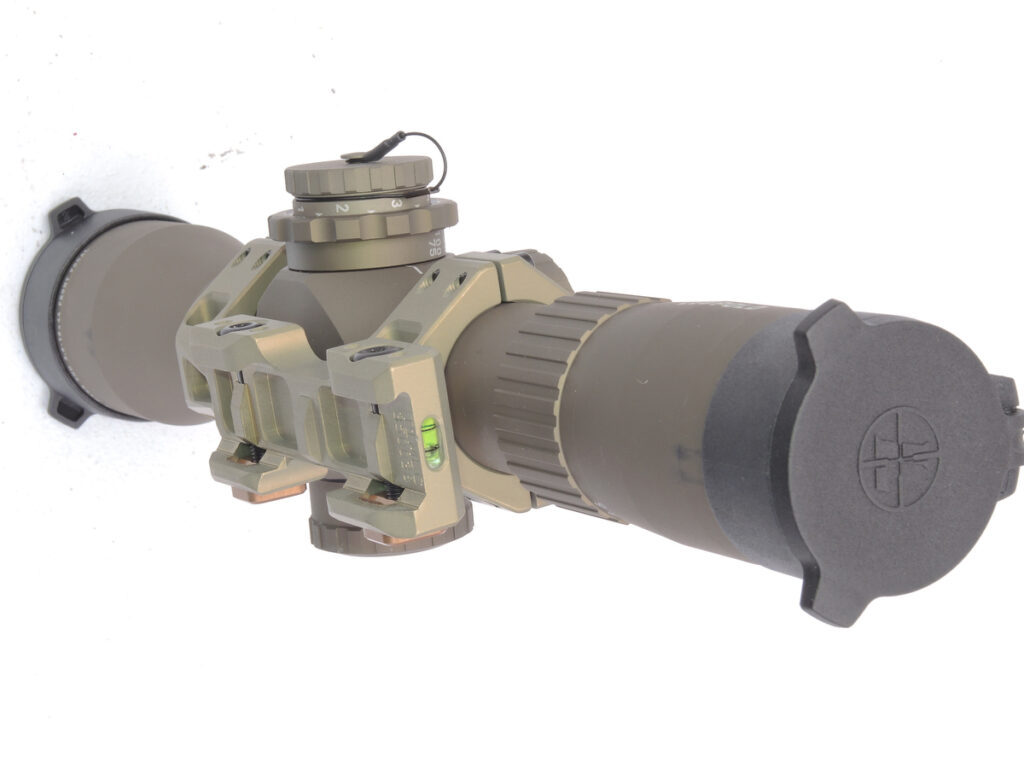

OPTIC

World renowned U.S. optics manufacturer Leupold was chosen for the L129A2-issue optic. The exact model is the Mark 5 HD 3.6-18×44 (M5C3) in desert IR finish (catalog no. 183456). It has a 35mm tube—a tube size that’s still gaining in popularity—that needs to be taken into account when selecting an optic mount. The reticle is the Tremor 3 and is illuminated with a 5-minute time-out to save batteries.

The Mark 5 HD is a workhorse. It’s robust; the controls are not going to fail; it’s first focal plane, which is pretty-well accepted in military circles as the best for the job. Plainly put, with FFP, no matter your magnification, the hash marks are always the same in relation to the target. 0.2 mils is always 0.2mils, no matter what magnification you’re at. This makes it much easier to judge windage and drift; it’s just very quick.

The Mark 5 HD is waterproof and fogproof, will withstand a lot of impact and extreme climate conditions. It has three full revolutions of elevation adjustment, so it can handle longer range jobs. While the L129A2 is a DMR and SSW, you can see from our targets that the performance was excellent at range. At 1100m, the optics were crisp, and with the flat-shooting 6.5 CM, we had excellent results.

To the left is the power selector ring — your “zoom.” It has a valuable 5:1 magnification ratio, giving you five times more magnification at high power than at low power. We found magnifications changes to be smooth, easy to control, and liked the system. In the lower right of the picture is the windage adjustment knob, and on top, the elevation adjustment knob with the elevation lock release button prominent at the rear. The controls are well thought out and easy to use.

The control knob in the lower part of the picture is the side parallax adjustment and illumination control knob. The outer control knob denotes brightness, and in between levels there are “off” positions. This allows the shooter to set the optic in “off” right next to the preferred illumination level. Very fast and handy if you know your preferences in various light levels.

The Pixels On Target Thermal Sight (not shown) was chosen for the Thermal part of the system.

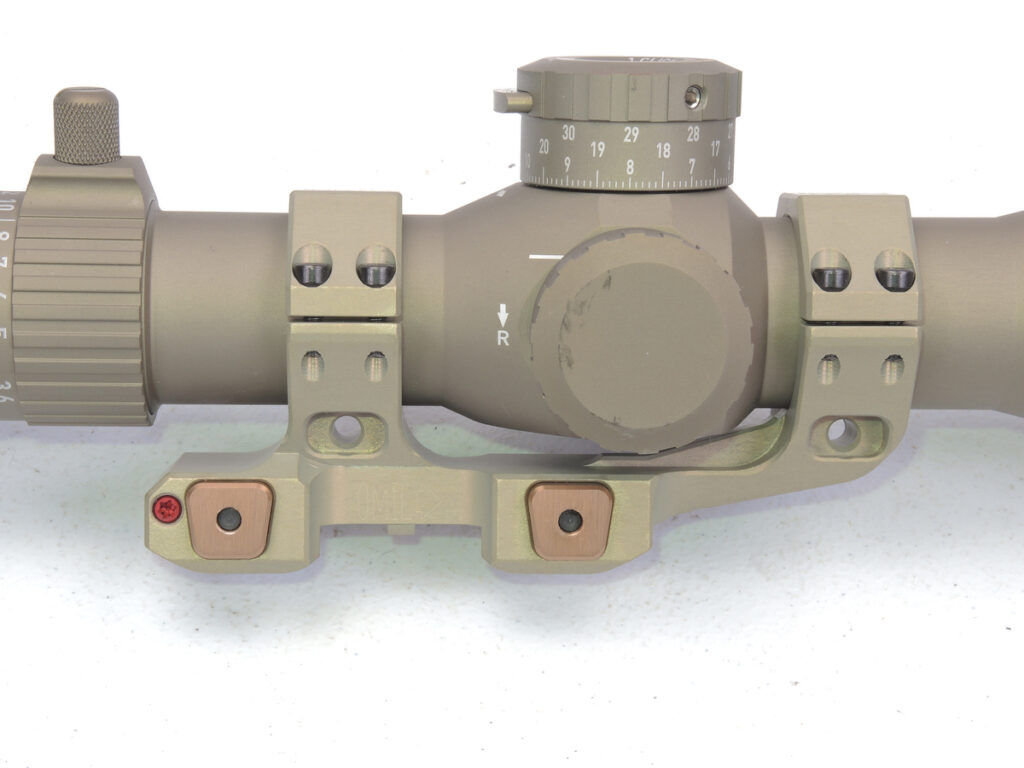

OPTIC MOUNT

The optic mount chosen is a very robust and compact one-piece cantilever monomount made by TIER-ONE of the U.K. Since the scope is a 35mm tube, the mount weighs 7.19 oz (204g). The mount is made from 7075 T6 aluminum, the same as many of the AR family firearms are, and is robust enough to withstand heavy recoil, having a large scope clamping area. Its finish is a mil-spec 30-micron hard-anodized finish.

Looking up underneath the mount, the solid contact with the monolithic rail is evident. Also, there is an anti-cant bubble level (replaceable) in the rear mount base. We found it easy to use for a quick level reading using the left eye; it’s very convenient without the common protrusion many scope levels have.

SUPPRESSOR

The adopted suppressor is the HUXWRX HX-QD Helix 7.62. The company’s statement of purpose is very telling, setting them apart from many other suppressor companies.

“HUXWRX Safety Company is a human exposure workshop dedicated to building products that are optimized for the safety and health of our customers, without compromising efficiency or performance.”

HUXWRX was at one time OSS Suppressors, a successful and innovative manufacturer with their “OSS Flow-Through” technology. I met the new owner and we discussed his vision. He was adamantly focused on the “safety” aspect of his product. With as much damage as firearms use has done to the health of end users, this is pretty refreshing. The toxic gas mitigation being discussed, many shooters have serious issues with heavy metals in their blood, is addressed in the HUXWRX system using a series of helical coils to decrease blowback, and actually “blow forward.”

Our tests at the range confirmed the claims about the gas-forward operation of this system. We compared brass from a 6.5 CM direct gas rifle using an older, screw-on can with the brass from suppressed L129A2, and the difference was clear. A lot less backflow, hardly any staining on the brass from the HUXWRX Flow-Through can. Their design works. As far as noise suppression, we didn’t do a full test on this. We plan on it later with the Larson Davis 800B meter. It was clear the HUXWRX suppressor tightened our groups, as expected, and was well within the sound suppression desired. Performance is expected to be in the 136-139 dB range, and to the ear, it sounded right.

The suppressor weighs 19.4oz (550g) and is made from 17-4 heat-treated stainless steel and Grade 5 titanium, is 1.62 inches in diameter, and 7.45 inches long — it only adds 6.85 inches to the barrel length. Finish is a C-series Cerakote in FDE.

The front endcap of the suppressor has spiraling holes venting forward from the helical design.

The HUXWRX Torque Lock system is patented and keeps the suppressor squarely mounted to the QD muzzle device. This is threaded 5/8-24 for most AR-10 type barrels. In this photo, the muzzle device is inside the suppressor for storage.

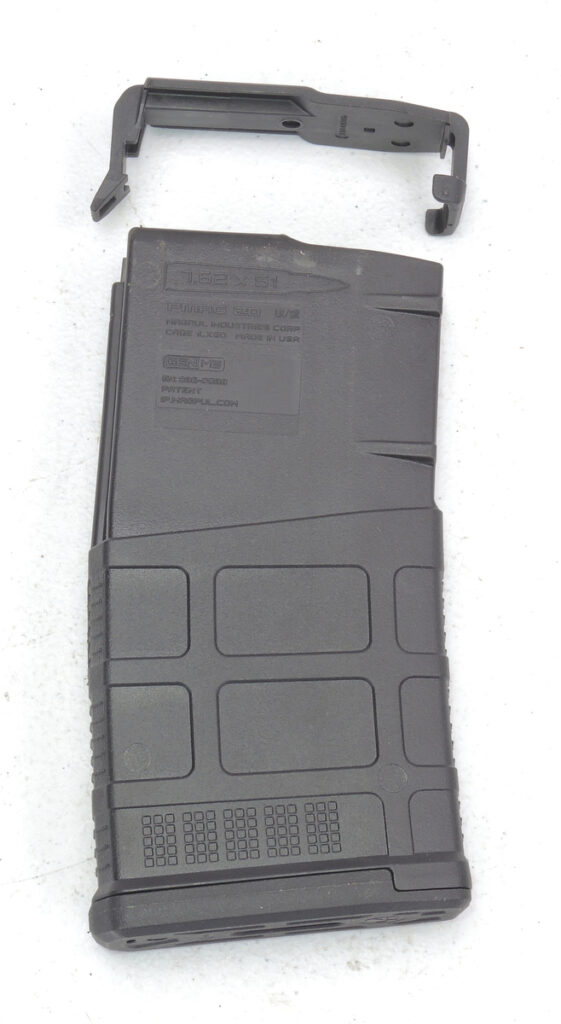

MAGAZINE

The magazine chosen for the system is the 20-round Magpul PMAG Gen M3. It’s a 7.62×51/6.5 CM capable magazine and is very reliable. It uses a stainless-steel spring, an anti-tilt, self-lubricating follower, and the internal curve of the magazine is constant. PMAGs are well known for their reliability. They’re lightweight and very popular. The 20-round mag weighs 5.7 ounces empty, is 6.5 inches long, and is SR-25 patterned.

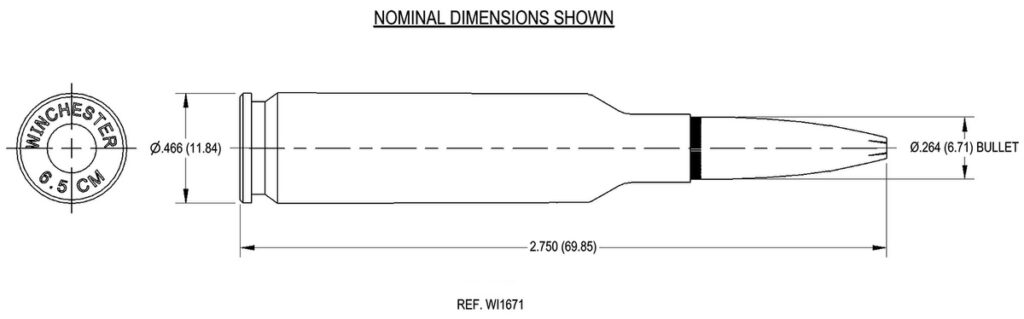

AMMUNITION

There really isn’t a settled-on mil-spec 6.5 CM cartridge as of yet. I know there are people who will beg to differ on that, however, I’ve yet to see the final, this-is-it, last straw dropped, documents. That said, most of us want to see a 140-grain open tip match cartridge with a muzzle velocity of about 2700fps. Olin-Winchester has such a cartridge, and since they operate the Lake City Army Ammunition Plant (LCAAP) and produce much of the U.S. and other militaries’ ammunition, we went with their offering. At this point, the cartridges don’t have military style sealing or primer crimps. Still, the muzzle energy is impressive, and while we don’t have access to the terminal or wound ballistic data, the people that do have that available are looking very favorably at this Winchester round.

Ammunition Used in the Test:

Winchester 6.5 Creedmoor (140-gr) Match BT Hollow Point

| Symbol | S65CM |

| Shellcase | Winchester 6.5 Creedmoor Brass |

| Bullet | 140-grain (9.07 grams) Boat Tail Hollow Point |

| Bullet Construction | Brass jacket, lead core |

| Diameter | 0.264 inch (6.71 mm) |

| Powder | Clean burning, low flash |

| Primer | Winchester non-corrosive primer, boxer type |

| Velocity | 2710 fps (826 m/s) at muzzle |

| Test Barrel | 24-inch (61.0 cm) standard SAAMI test barrel |

| Energy | 2283 ft-lb (3014 joules) at muzzle |

| Waterproofing | None |

| Contact | Olin Winchester, LLC |

| URL | www.winchester.com |

ON THE RANGE

Our test firing was done at the Boulder Rifle & Pistol Club in Boulder City, NV (BRPclub.org). BRPC is an excellent, well maintained range system, with everything from archery to long range shooting out to 1100m. BRPC is well known in Nevada, especially with the events they host during SHOT Show.

Our accurate shooter is Dennis Powell. These are his targets. The reasonably accurate shooter is Dan Shea, we’re not showing his targets.

| Date | 16 Dec 2023 |

| Time | 0635 |

| Elevation | 1933 ft |

| Wind | 1.2 mph |

| Temperature | 50.2°F |

| Humidity | 24.1% |

| Dew Point | 13.5 |

| WB | 36.1 |

| Barometric Pressure | 27.86 inHg |

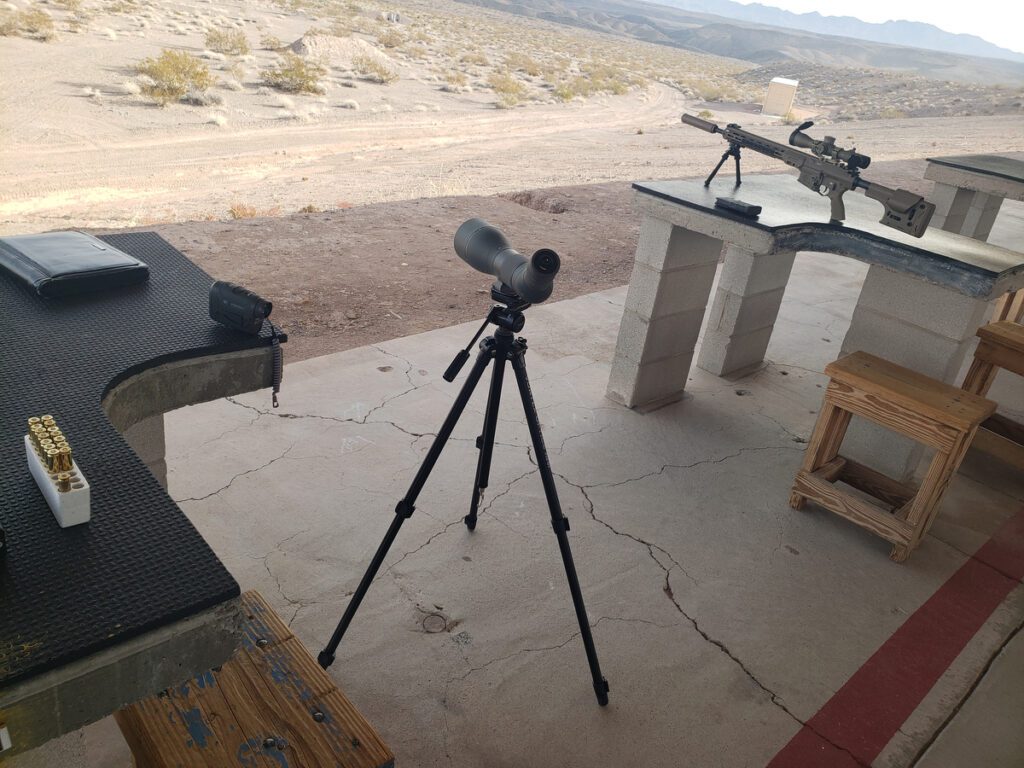

Set up at the Boulder Rifle & Pistol Club long range, out to 1100m. Left; Vortex Razor HD 4000 GB laser range finder. On tripod; Vortex RAZOR HD angled 22-48×65 spotting scope on a Vortex Tripod. Both the spotting scope and range finder are written about in more depth in the Barrett MRADELR article. Right, L129A2 Designated Marksman Rifle, ready for firing.

At 100m, the sighting-in process was fairly quick. We were bore-sighted onto paper, lower right, walked across the target and ended with three in the center that were at 0.5 MOA. Our next groups got to 0.34 MOA, then we moved out to further and further targets.