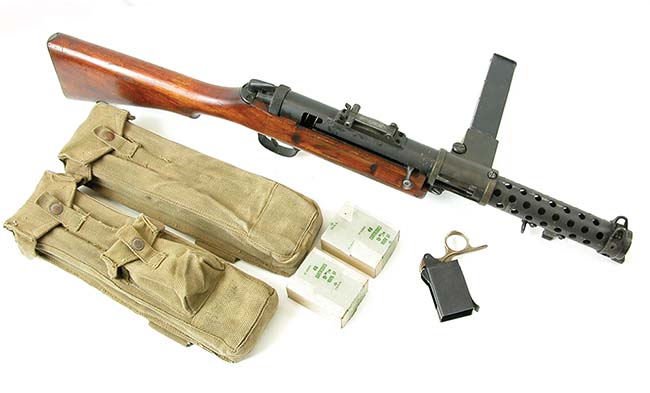

ABOVE: The MkIII Sten was designed to speed production and reduce cost. The integral design proved inferior when tested against an MkII, and production was terminated after a brief production run.

Part 1 in a Series About the British Submachine Gun

The humble Sten gun was borne of desperation in a troubled time, as England was standing alone against the unrelenting German Army. World War II started when Germany invaded Poland on 1 September 1939. On 17 September Russia joined Germany and invaded Poland from the east. By 6 October the last pockets of Polish defenders were silenced. In April 1940, Germany invaded Denmark and Norway. Denmark capitulated after a few hours; Norway was conquered within two months. On 10 May 1940, Germany launched an offensive against France and attacked the neutral nations of Belgium, the Netherlands and Luxembourg. By 25 June they all had been overrun. The well-prepared German army was rolling over countries in weeks. England was next on Hitler’s agenda.

England, first shunning the concept of the submachine gun, but facing an imminent cross-channel invasion by the Germans, soon changed her mind. Desperate, England began purchasing expensive Thompson submachine guns from the U.S. Unfortunately, many ships crossing the Atlantic Ocean, transporting the Thompsons and ammunition, became victims of German U-boat attacks.

The first British submachine gun was the Lanchester, which was copied from a captured German MP28 II. The Lanchester proved to be far too labor intensive to make; a less complicated design was needed. The country was quickly running out of cash and needed cheap indigenous submachine guns and lots of them. Enter Reginald Shepard and Harold Turpin, credited with designing the Sten gun.

The first prototypes were designated as the T-40, quickly followed by the Carbine, Machine and Sten MkI. The MkI had a few features, like the handguard, folding foregrip and a flash eliminator that were considered unnecessary. This soon resulted in the MkI* Sten. However, even the MkI* still required too much time to make; an even simpler weapon was needed. The Sten prototypes were made by the Philco Radio Works in England. Production MkI and MkI* Stens were manufactured by the Singer Manufacturing Company in Scotland.

The Sten MkII

The Design and Development Department RSAF Enfield was engaged to simplify the MkI* design to further to reduce the time required to produce them. The basic function remained the same, but the Sten MkII featured an easily detachable barrel and buttstock, making the weapon both compact and concealable—two features that would make the Sten suitable for paratroopers and for air-dropping to various resistance groups. Approximately 2,600,000 Sten MkII submachine guns would be produced by the British during the war. The Sten is perhaps the most copied and used submachine gun, seeing service many years after World War II ended. The British MkII Stens were manufactured-assembled by ROF (4) Theale, ROF (6) Fazakerley, BSA and RSAF Enfield.

The Wrapped Receiver MkII

The wrapped receiver concept was another idea to expedite production by making the receiver and trigger housing out of a single piece of formed sheet metal; however, after the “wrapped” receiver Stens were in service, difficulties arose. Most of the problems were associated with the trigger housing. The top and bottom of the housing were open, resulting in a lack of support. In addition, the top opening of the housing exposed the trigger group to debris and dirt. An attempt was made to recall all of the “wrapped” Stens for destruction, but a few escaped the torch.

Sten MkIIS

The Sten MkIIS was the suppressed model of the Sten, the letter “S” suffix representing “Special Purpose.” The requirement for a “quiet” Sten originated for use by resistance fighters. The suppressor’s barrel was designed to bleed off pressure from a fired cartridge to reduce the bullet’s velocity to a subsonic level. To ensure proper function with the pressure reduction, a shorter recoil spring and a lighter bolt were used. The “Special Purpose” Sten was to be fired semiautomatically, but the full-auto option was retained for emergency situations. There were several types of suppressors fielded, including the 22.5-inch long SOE type. The SOE was the Special Operations Executive, organized to conduct covert espionage, sabotage and reconnaissance operations in occupied Europe during WWII.

Sten MkIII

The MkIII model of the Sten was conceived in order to lower cost and speed production. The receivers were produced by the “wrapped” method from a single piece of sheet metal, with the receiver spot welded along its top seam; the front sight was formed as part of the seam. The magazine housing was spot welded to the receiver and thus non-moveable. The barrel was permanently attached to the receiver by rivets. A trigger housing, similar to that of the MkII, was welded to the bottom of the receiver. The powers that be decided that production of the MkII should be terminated and all efforts concentrated on making the MkIII. A comparison trial was held. In nearly all categories the MkII bested the MkIII. As a result of the trial, production of the MkIII Sten was ended. Mark III Stens were manufactured by Lines Brothers Ltd, London.

Sten MkIV

There were several versions of the Sten designated as an MkIV; all were non-production prototypes. One was basically a MkII with an underfolding buttstock and a redesigned trigger group that fired semiautomatic only. Another version, the MkIV-A, was also basically an MkII model, fitted with a short barrel-with flash hider, enlarged trigger guard, a pistol grip and side-folding buttstock.

Sten MkV

The next evolution of the Sten was the MkV model. The Mark V was introduced in early 1944 and remained in British service until 1956 when it was replaced by the MkIV/L2A3 Sterling submachine gun. Approximately 530,000 MkV Stens were produced in England from 1944 to 1945. The MkV featured a rear wooden pistol grip and the protected front sight assembly from the No. 4 Enfield rifle. The barrel was designed to fit the No. 4 rifle bayonet as well. The trigger group parts are the same as the MkII Sten except for the trip lever. The bolt is also similar to the MkII except the bottom of the front bearing surface was cut to clear the tipping lever. The trigger group and safety notch in the receiver are located 1.3 inches forward to accommodate the rear pistol grip. A fixed wooden buttstock was fitted, which along with the pistol grip made for a more stable platform. MkV Stens were produced by the Royal Ordnance Factories ROF Theale and ROF Fazakerley.

Sten MkVI

The Sten Mark VI was the suppressed version of the MkV. The suppressor or “silencer” was similar to that of the MkIIS but modified slightly to work on the MkV Sten.

Other Sten Copies

One of the attributes of the Sten design was it could be manufactured in the most basic workshop, of locally obtained materials. Easy to produce and concealable when disassembled, the Sten MkII proved an ideal weapon for resistance groups during World War II. The Sten gun became the symbol of the underground groups opposing German occupation.

Canada

Early in 1942, the Long Branch factory began production of the Sten gun. The fit and finish of the Canadian Stens were generally considered to be better than the British guns. However, Canada was not under direct German threat or being bombed, as England was during the 1940s. Approximately 134,000 Sten MkII submachine guns were manufactured at the Long Branch Canadian plant along with 1 million magazines. The Sten magazine housings were marked STEN MK II, LONG BRANCH along with a date of manufacture.

China

During World War II, the Long Branch, Canadian factory made approximately 73,000 Sten MkII submachine guns to aid China. The magazine housings were marked with Chinese characters on the top and Long Branch markings and date on the bottom.

A Chinese-made copy of the Sten MkII was designated as the M38. The M38 was a near exact copy of the British-made version. The Stens were manufactured in Chinese Nationalist factories. After the Communists forced the Nationalists out of China, they took over the factories that were producing weapons. One way to identify a Chinese-made Sten is by the straight bottom of its trigger housing cover; another is the lack of a selector button—the M38 submachine gun does not have a semiautomatic feature. After World War II, many of the countries that fell under Communist influence adopted the 7.62x25mm Tokarev cartridge for their pistols and submachine guns. The Sten was one of the many small arms that were converted to fire the Communist round. Chinese-, Canadian- and British-made Stens have surfaced in enemy hands in both the Korean and Vietnam Conflicts.

Australia

During 1941, England sent drawings and samples of their Sten gun to the Australians. The Australian military was not impressed. The Australians decided to design a more refined version of the Sten. The Australian model was called the “AuSten.” The name “AuSten” was simply a contracted version of the words Australian-STEN. The AuSten had features of the British Sten and a few from the German MP40 maschinenpistole. In place of the Sten’s simple, fixed firing pin bolt and recoil spring, the AuSten used the bolt and telescoping recoil spring, with the attached firing pin design of the German MP40. A second feature copied from the German MP was a complicated folding metal buttstock. The AuSten had rear and front pistol grips with plastic panels. Many components were made by die casting. The AuSten submachine guns were produced by Diecasters Ltd of Melbourne and Carmichael Ltd of Sydney. Production spanned from 1942 into 1945. By 1944, the AuSten was replaced with the “other” Australian submachine gun, the proven Owen. The best part of the AuSten was its cast magazine loader, sought after today for loading Sten magazines.

New Zealand

When World War II erupted in Europe in 1939, countries like New Zealand and Australia were not yet under any threat of invasion. However, after Japan entered the war in 1941, their swift moving island-hopping campaign brought the Japanese army uncomfortably close to New Zealand and Australia, who soon found themselves under threat of a Japanese attack. The British had shared their plans for the Sten guns with New Zealand. Initial production of Stens in New Zealand was intended to protect their airfields. The Sten MkIIs made in New Zealand are nearly identical to their British counterparts. There was also a second pattern of Sten made in New Zealand referred to as the “LP” or “local pattern.” The local pattern Sten differed from the original British design. The LP receiver was made from a rolled piece of sheet metal and welded along the top seam, similar to that of the Sten Mark III.

Denmark

Denmark was occupied by German forces in 1940; The Danish Resistance Movement was an underground insurgency organized to resist the German occupation. To arm the resistance members, the British air-dropped a number of Sten MkII submachine guns and other supplies into Denmark. Resistance groups’ members often wore long topcoats to conceal their Stens from the Germans. To provide enough weapons for the growing number of members, resistance groups began locally manufacturing copies of the Sten. The parts were made in a large number of small shops. There were several variations of the Sten made by the different resistance organizations, of available materials. Producing barrels was a problem, largely solved by boring and re-rifling old rifle barrels. One Danish Sten copy was designed to use Suomi magazines. The Ringen Sten was a Danish design produced in small workshops using a number of aluminum castings.

Norway

After the German invasion of Norway in 1940, underground partisan groups quickly formed. After examining the British Sten gun, it was decided to make them locally. The construction of the Sten guns made in Norway often had rough welds and a poor finish. As in England, many of the Sten gun parts were made in many small scattered workshops and assembled at another location. One feature of a Sten made in Norway was the trigger retaining pin that was located on the left side of the gun, instead of on the right like the British-made Stens. To conceal their weapons production from the Germans, many of the Norwegian-made underground Sten guns were often stamped with British markings to conceal their local origin.

Poland

After Poland surrendered to German forces in 1939, several groups were formed to resist the German occupation. The ideal weapon for such groups was a submachine gun, but few were available. The British air-dropped Sten MkII submachine guns in late 1942. Although the Sten was a primitive-appearing weapon, it could kill an enemy soldier as dead as any other. The Polish underground quickly found that although crude, the Sten gun could be easily reproduced. The Poles went on to produce more Sten copies during World War II than any other country. The quality ran from poor to as good as those made in English factories. One of the best was made in Warsaw and proudly marked with the stylized Polish Eagle and STEN PM (Pistolet Maszynowy).

Germany

Imitation is the sincerest form of flattery. Although the Sten gun had many condescending names bestowed upon it by soldiers and resistance fighters alike, the weapon was copied by Britain’s nemesis Germany. The Germans intercepted a fair number of Stens that were air-dropped to resistance groups. As the war continued in the allies’ favor, the Germans needed more weapons, primarily to arm the Volkstrum, an organization of civilians ranging in ages 16 to 60 who were not already serving in the military. The Germans began to issue the captured Stens, designated as the MP748(e), to the Volkstrum. The successful fielding of the Sten convinced the Germans that the weapon had merit, and they set out to produce copies. In 1944, the Mauser company was issued an order for 10,000 Sten gun copies code-named “the Gerät Potsdam.” The German copy had a horizontal magazine housing and used Sten and MP28/II magazines made by the Haenel company.

The Gerät Neumünster (MP 3008)

The Gerät Potsdam began as an exact copy of the British Sten, but there was still a desire to make it cheaper and faster. Mauser had not made any significant changes to the weapon’s design but received a request to alter the design to expedite production. One of the changes to simplify the Gerät Potsdam was to attach the magazine well by welding it in a vertical position and to design it to use MP40 magazines. The bolt had to be modified for the new magazine position. The barrel was permanently pinned in place. The unofficial name “MP 3008” was bestowed on the Gerät Neumünster and was due to its numerical identification on an ordnance equipment list.

Indonesia

Indonesia was another country that copied the Sten design, with a few modifications, such as a right-side folding buttstock and a protected rifle-type front sight. The copies were crude and features varied.

Israel

After World War II ended, Sten guns made by the British and others began appearing in conflicts around the world—the Sten design endured. Many British-made Sten guns were used and others locally manufactured and fielded by fledgling countries like Israel. In addition to the British-made Stens and those made in small workshops by resistance groups like Haganah, Taas (Israel’s state-run military arms factory) produced a number of Sten guns.

There are a number of movies available on DVD that feature WWII resistance groups using the Sten gun; two very good ones are: “Flame & Citron” (2008) and “Max Manus: Man of War.”

Recommended Reading

The Sten Machine Carbine

Peter Laidler

Collector Grade Publications.