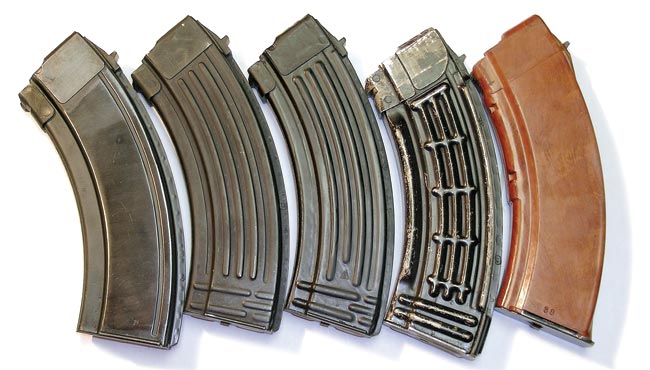

Identifying all magazines, for all AK variants, would be of such a large magnitude that it would be completely impractical to attempt. As such, this effort is limited to 7.62x39mm magazines with a capacity of 30 rounds or less, and which don’t need to be modified to work in a standard AK-47. Even with this seemingly narrow scope the project proved dauntingly large, and continued to grow as new variations showed up.

Soviet Union

When the Soviet Union started production of the AK-47 in late 1948 at the Izhevsk Machine Plant, also known as Izhmash, it came with a 30-round magazine that has come to be called the “Russian Slab-Side.” It gets its name from its smooth stamped sides and was produced only by the Izhmash factory. They are relatively rare as the design was replaced before AK production was started at another factory.

The Russian Slab-Side magazines are generally covered in inspector stamps, but the Izhmash factory mark (feathered arrow in triangle) will be found stamped low on the back of the mag’s body. Made from thick 1 mm steel, it is without doubt extremely durable, but heavy. They originally had a blued finish, but many appear to have been later refinished with a black enamel coating.

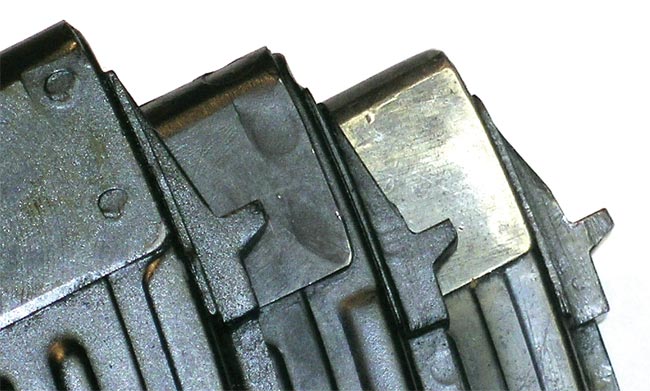

About the time that the Type III AK-47 was adopted in 1954, a new lighter 30-round steel magazine was introduced. Stamped from thinner steel (.75 mm) this design featured ribs in the body for added strength. The body, as with the earlier Slab-Side version, was formed from two stamped metal halves that are spot welded together along the front and along the rear flanges (referred to as the mag spine). The body features three outward and one inward facing longitudinal ribs, as well as five outward facing horizontal ribs along the bottom of the magazine. Three of these horizontal ribs are noticeably short, and basically just wrap around the bottom rear of the mag. The first ribbed mags had the inward facing rib at the rear of the mag’s body going strait up and under the plates that reinforce the feed lips. This type of mag was produced by many other countries, and I will refer to it in the future as the “First European Ribbed Type.”

The earliest Soviet ribbed mag, the “Izhmash Back-Stamped Ribbed Mag”, has the Ishmash factory mark stamped on the bottom-back of the mag like the Russian Slab-Side mag. At first, these mags were blued, but this was eventually changed to a baked-on black enamel finish. Izhmash reportedly switched to a baked-on enamel finish on its AKs shortly before production of the AKM model began in 1959. The followers on these early Izhmash ribbed mags will have a large pill shaped bulge with a hole through its front left side. This bulge does not extend to the rear of the follower.

Eventually, the Izhmash factory mark was moved to the spine, and this version is generally referred to as the “Early Izhmash Spine-Stamped Mag.” This was followed by a new follower with a longer thinner bulge on it that extends to the back of the follower. The hole through the front left side of the earlier follower’s bulge was also eliminated. The hole’s purpose seems to have been the prevention of a stuck follower from suction in a heavily greased mag, but this had apparently been deemed unnecessary.

At some point the dies used by Izhmash to stamp mag bodies were redesigned. The inward facing rib at the back of the mag now stopped short of the lip reinforcement plates, and turned at a 90 degree angle toward the rear of the mag. This rib resembles an upside down and backward “L”. This type of mag body was also made by many other countries, and I will refer to it in the future as the “Second European Ribbed Type”.

As would be expected; these mags will be found with the Izhmash mark stamped on the spine, and with a baked-on black enamel finish. Collectors generally refer to them as a “Late Izhmash Spine Stamped Mag.”

In 1960, the Soviet’s Tula arsenal started production of the AKM. All Tula rifles, and steel mags, were finished with a baked-on black enamel finish. These mags are of the Second European Ribbed Type, and will usually have a fair number of inspector stamps on both the spine and its lower sides. Tula’s factory mark is a five pointed star that, when found, is always on the spine. Tula steel mags are relatively rare as they were only made for a few years before production was switched to the new AG4 plastic type.

The last steel mag produced by the Soviets is referred to by collectors as the “Izhmash Side-Stamped.” It is basically a Late Izhmash Spine Stamped mag with one very noticeable difference. On the mag’s left side, the middle outward facing vertical rib stops well before the other two, leaving a blank area at the bottom of the mag where the Izhmash factory mark is prominently stamped. These mags carry a black enamel finish, and as the name implies, were only made by Izhmash.

During the mid to late 1950s the Soviets also produced an aluminum 30-round magazine for the AK generally referred to as the “Aluminum Waffle” by collectors because of its very distinctive ribbed pattern. This mag is made entirely of aluminum, except for its spring, and carries a black enamel finish. They will be found with multiple inspector stamps on both the spine and lower sides. Made by Izhmash, most will show its factory mark on their spine. They were probably discontinued in favor of the steel mag’s greater strength. Soldiers have been known to use their mags as hammers, and even bottle openers.

During the early 1960s, the Soviets introduced a new 30-round AK mag made from a glass-fiber reinforced plastic called AG4. This mag was molded in two halves that were then joined with an epoxy adhesive with steel front and rear lugs being molded into the mag’s body. The follower, keeper/takedown plate, and floorplate also remained steel. These “Russian AG4 Plastic Mags” were made by both Tula and Izhmash. The respective arsenal’s mark being molded into the bottom right side of the mag while the mold number is on the bottom left side. Inspector marks were stamped onto the body of the mag with permanent ink. It is interesting to note that these mags never fully replaced the steel mags in Russian service. Reportedly, this was due in no small part to soldiers fears that, if they were injured, shards of a plastic mag would not show up in an x-ray.

Between the two manufacturers; a large number of variations of the Russian AG4 plastic mag exist. Very early mags had a mold line that gave the impression of long top, and were brown in color. The color was quickly changed to a much more common reddish-orange and this was then followed by a mold re-design that moved the mold line higher up on the body. Mags will also be found with, and without, a noticeable ridge running down the back of the mag, and at least four types of floorplates are known to exist. Izhmash also had at least two sizes of its factory mark molded into the body.

During the 1980s, the Soviets experimented with a plum colored polymer AK-47 mag at a time when they were manufacturing a similar mag for use in their 5.45x39mm AK-74 rifles. Like the AK-74 mag, steel lugs were molded into the body and it used a steel floorplate. Criss-crossing ribs, however, were molded into the body for added strength, and possibly for quick identification as to its caliber. These “Russian Plum Waffle Mags” unfortunately lack any markings to indicate the arsenal that made them. Only a handful of these 30-round mags have made their way into the U.S., and it is probably the most sought after AK-47/AKM mag.

At the present time, the Russian Izhmash factory is making a 7.62x39mm black polymer 30-round mag for export sales with its AK103/AK104 rifles. None of these have ever been directly imported into the US, but some have reportedly made their way here through a third country. The mag made for Izhmash’s Siaga version of the AK are often modified to work in a regular AK, and incorrectly represented as one of these.

Bulgaria

In 1958, the Bulgarians began producing the AK-47 at their Factory 10 under Russian license. The earliest Bulgarian steel mags were of the First European Ribbed Type, and are seen stamped with either a “10” or an “E” in a double circle on the spine. The “E” in double circle may have come about in 1964 when the Bulgarian Factory 10 was temporarily re-named as the United Industrial Plant “Friederich Engels,” but more likely represent a different factory. All of these mags appear to have a blued finish, and have the large pill shaped bulge, with hole, on their followers. The follower’s bulge is similar to the earliest Russian ribbed mags, but is not rounded as much.

The next Bulgarian steel mags were of the Second European Ribbed Type. These will be found with both the earlier follower and a new follower featuring an elongated bulge without a hole in it. All the marked ones so far observed carried the “E” in double circle stamp on the spine. They all appear to have a phosphate finish.

The third Bulgarian steel pattern is a unique type. The inward facing rib on the rear top-left side of the mag expands backwards in a slanted concave shape to the feed lip reinforcement plate. On the right side it expands backwards in a slanted convex shape. Early mags appear to have a phosphate finish while the later/majority have a black enamel finish. Most of these “Late Bulgarian Steel Mags” are unmarked, but a few have shown up stamped with either an “E” in double circle or “25” in double circle stamping on the rear spine. The “25” in double circle represents Optico Electron Inc., a well known Bulgarian manufacturer of polymer AK-74 mags. (Author’s note: In the future I will refer only to the number of outward facing ribs on a steel mag. The inward facing rib at the rear will be considered a “given” and covered by its type description.)

Around 2000, a series of experimental 30-round polymer Waffle mags were imported by Magua Industries from Bulgaria. Imported in only small quantities; they were advertised colored either arctic white, blue, clear, gray, hunter green, olive green, plum, or yellow. However; only the arctic white, clear, hunter green, and olive green colored mags appear to have made it here in any quantity. They will carry the “10” in double circle factory mark molded into the left side. These mags were strengthened by having a thin sheet of steel, as well as steel front and rear lugs, embedded within the polymer body. The follower and keeper/takedown plate were made of polymer, but the floorplate remained a steel stamping. The clear polymer mags, for obvious reasons, had the steel sheets left out of the body, and have suffered badly from cracking at the lips due to this fact and the type of polymer used.

A few years later large quantities of these 30-round polymer waffle mags, now black in color, started to be imported into the US. Interestingly, they will sometimes be found with, and without, a mold number on the right side. These mags were designed for military sales, and have shown up in Iraq in large quantities with the new Bulgarian AKs supplied to the post Saddam army.

The 1994 Import Ban of so-called “assault rifles” led to the more politically correct thumbhole stocked AKs without bayonet lugs. The Bulgarians produced the SA93 and SLR95 “sporting” rifles, and exported them with newly developed 5 and 10-round shortened versions of the black Bulgarian Waffle. The bodies of these magazines are the same regardless of whether it has a 5 or 10 round capacity, but capacity is increased to 10 rounds by the use of a shortened follower and keeper. No factory markings will be found molded into these mags. The follower is marked with a “5” or “10” in silver paint to indicate its respective capacity.

KVAR Corp. has recently had the Bulgarian arsenal produce waffle mags for them in special colors to match the US made polymer stocks it sells. OD green mags have been made in 5, 10, 30, and 40-rounds capacities. Plum mags have been made in 30 and 40-rounds capacities.

In early 2007 another type of polymer 30-round mag was imported that is usually referred to as the “Bulgarian Bullet Mag.” The name comes from the rough image of seven 7.62x39mm cartridges molded into each side. The mag also has “Cal. 7.62×39” molded into the bottom of the left side, as well as three small stars molded into the bottom right side. The manufacturer, ISD Bulgaria, Ltd., placed no arsenal marking on these mags to indicate that they made them. The polymer body is reinforced with thin sheets of steel, and the floorplate remains a steel stamping. The follower and keeper are made from polymer but, more importantly, so are the front and rear lugs. Unfortunately, the rocking motion used to insert an AK mag in a rifle will eventually wear out plastic lugs, and one should expect only a fraction of the lifespan of a military steel mag.

One feature of these mags that has caused some consternation with first time users is its so-called self cleaning feature. As the follower rises up it forces the feed lips slightly further apart, and supposedly crud up and out. The increased width of such an empty mag sometimes prevents its insertion into a rifle; particularly those with US made receivers, but problems have been encountered when inserting empty mags into factory built AKs. Inserting three rounds in a mag allows insertion in any AK.

The “bullet” images molded into the mag’s body have never been much of a hit with the shooting community. In late 2007, the Bulgarian factory redesigned the molds to remove the bullet images and replaced the three stars on the bottom right side with an unknown symbol believed to represent the factory. The “CAL. 7.62X39” marking on the bottom left side was also made a little more prominent. Otherwise, the mag remained the same and this new version is generally referred to as the “Bulgarian Slab-Side.” In July 2008, a clear polymer version of this mag was introduced to the US market. The “Bulgarian Clear Slab-Side” lacks the steel reinforcement sheets in its body for obvious reasons.

In mid-2008, the unique Late Bulgarian Steel Mag started showing up in the U.S. with the same black polymer follower and keeper used in the Bulgarian Bullet and Slab-Side mags. It would seem that ISD Bulgaria is manufacturing these new hybrid mags in order to keep the price competitive with military surplus. These mags are finished with a baked-on black enamel finish, show excellent workmanship, and work very well.

East Germany

East Germany received a license from the Soviet Union in 1957 to produce the AK-47, but production didn’t start until 1959. East German 30-round mags are all of the First European Ribbed Type, and are generally known for the excellent quality of their salt blued finish. The follower is of a unique pattern having a bulge that is flattened at its rear, but rounded at the front. Early East German Blued Mags will almost always be found with two to six large thin block style letters stamped on the spine. There is no apparent pattern to the letters stamped on the spines and these are believed to be just inspector stamps. A single small number in an oval, such as “15”, “16”, and “29”, is also sometimes found stamped on the spine.

Much rarer, and largely unknown, is the Late East German 30-round mag. The body and follower remain identical to those of an early East German mag, but have a black phosphate finish. The thing that really makes this mag stand out is its unique floorplate. The floorplate’s normal oval shaped stamping, at its front end, has its rear edge flattened into a slanting straight line. The few of these mags that I have examined were unmarked.

Egypt

Egypt received a license to produce the AKM in 1971 and began production shortly afterwards initially using imported Russian parts. Egyptian 30-round mags, surprisingly, are of the First European Ribbed Type. Early commercial mags imported to the US were stamped “Made in Egypt” near the top of the mag on the left side. The glossy black enamel finish applied to the mag’s body and floorplate is often atrocious, showing obvious paint dripping. The follower, however, retained a blued finish. What really makes this mag stand out from other First European Ribbed Types is their welding patterns. The rear catch has unusual tear-dropped shaped spot welds, while the front lug and front edge of the mag’s body has round spot welds. The welding along the spine is neither round nor oval, and while sometimes indistinct, is best described as a blob.

Later both 30 and 5-round Egyptian mags were imported with a matte black enamel finish on the mag’s body, and with blued followers and floorplates. The follower pattern was slightly different on these mags, and the front lug was enlarged. The welding pattern, however, remained nearly identical. No factory markings have ever been identified on an Egyptian mag.